Team:Tokyo Metropolitan/Project/Fiber

From 2010.igem.org

| Line 5: | Line 5: | ||

<div style="width: 800px; margin-left: 75px; padding-top: 25px; padding-left: 20px;"> | <div style="width: 800px; margin-left: 75px; padding-top: 25px; padding-left: 20px;"> | ||

<font size="5"><b><i>E.coli</i> Fiber Project | <font size="5"><b><i>E.coli</i> Fiber Project | ||

| - | <a href="https://2010.igem.org/Team:Tokyo_Metropolitan/Project/ | + | <a href="https://2010.igem.org/Team:Tokyo_Metropolitan/Project/Fiber/Protocol">⇒Protocol</a> |

| - | <a href="https://2010.igem.org/Team:Tokyo_Metropolitan/Project/ | + | <a href="https://2010.igem.org/Team:Tokyo_Metropolitan/Project/Fiber/Result">⇒Result</a></b></font> |

<br><br> | <br><br> | ||

“More efficiency and Mass-product Of Bacteria Cellulose(BC) ” | “More efficiency and Mass-product Of Bacteria Cellulose(BC) ” | ||

Latest revision as of 16:17, 26 October 2010

“More efficiency and Mass-product Of Bacteria Cellulose(BC) ”

So,we are plannning to make E.coli that produces Bacterial Cellulose!!

Contents |

Introduction

What is Bacterial Cellulose?

| It is Cellulose that Bacteria produce. Especially, it is famous for which produced by Acetobacter. It is being used as commercial materials and foods. For example, nata de coco. But, in the future, we think that we can use it for kinds of fields!! More and More!!!! For example, the basis of the plate type display. Organic Electro-Luminescence, this photo, is very thin. Its thickness is 5centimeter. It will be possible to use as the basis material of display which is thinner than present one. |

Why do they use for kinds of fields?

|

First, this diameter is small. BC has 1/100-1/1000 size than plant Cellulose. Left photo is plant cellulose (PC). Their scale size is different. But we can see that BC is thinner than that. Second, BC can built more dense structure than PC. And the percentage of cellulose is more than that of PC. That is what degree of purity is very high!! By that, we have an advantage that the cost is low.

Therefore, BC is able to form dense structure. And we can make high quality filter. Another, BC has an advantage that we can suit ourselves to manufacture the vent size. And people use them for medical pad because they has dense structure and moisture-retaining properity. Third, if special plastic get through BC, they become a hard and thin material. This material is used for organic EL and electronic paper. Moreover, they are very hard and flexible. So, sounds pass on speedily. If we use for auto body, car become light and get good mileage. We expect to use for kinds of fields because BC has many material characterization. But the problem remains. The big issue is to product Cellulose. Low product and high cost. I heard a report that BC use technology is developing. So, if we solve that issue, our project has big meaning. |

|

Approach

Bacterial Cellulose Synthase genes

Our main task is inducing bcs(bacterial cellulose synthase) genes to E.coli from A.xylinum.

We use bcsA,B,C,D from Acetobacter.

Participations

- bcsA:polymerize and regulate Cellulose

- bcsB:save polymerize and regulate Cellulose as a catalyst

- bcsC:form pathway to belch out Cellulose

- bcsD:belch out Cellulose

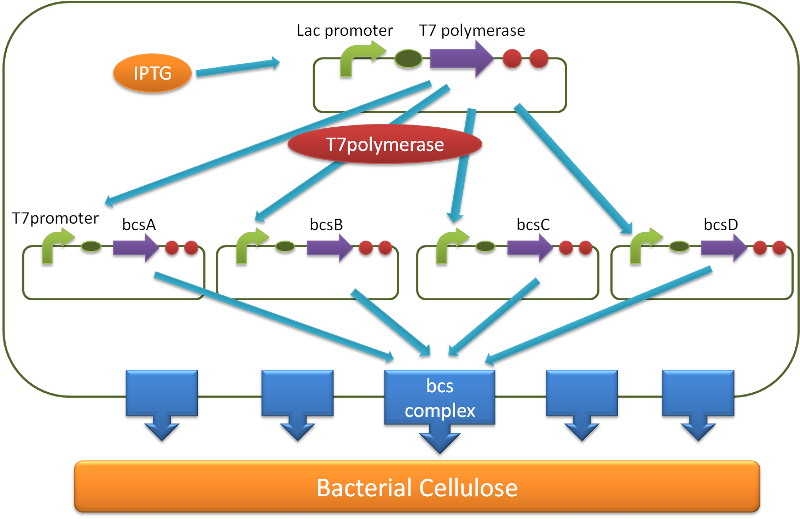

Overexpression System

In order to mass-produce bacterial cellulose, we suggest this system. We introduce the plasmid made of T7 promoter and bcs genes into E.coli. To have easy gene translation, we translate bcs genes individually. And we make another plasmid made of lac promoter and T7polymerase so that we can control T7promoter expression. It is known that E.coli mass-produce its proteins in log phase. So we have T7promoter to express in log phase and E.coli to mass-product bacterial cellulose.

Model

We designed this model.

Future

If this project is succeeded, we can contribute to put into practical use and develop BC. Then, new technology for Bacteria Cellulose will develop and our life style will go up!! And also if BC alternates plant pulp as paper product, we can contribute environmental issue.

What we put in Biobrick leads to make new Biobricks by combinning with ever parts.

Reference

- Yoko UMEDA,1 Atsushi HIRANO,1 Michio ISHIBASHI,1 Hideo AKIYAMA,2 Takuo ONIZUKA,2 Masahiko IKEUCHI,3'* and Yorinao INOUE4 (DNA RESEARCH 6, 109-115 (1999))"Cloning of Cellulose Synthase Genes from Acetobacter xylinumJCM 7664: Implication of a Novel Set of Cellulose SynthaseGenes"

- Shin Kawano,∗ Kenji Tajima, Yukako Uemori, Hitomi Yamashita, Tomoki Erata, Masanobu Munekata, and Mitsuo Takai (DNA Research 9, 149–156 (2002))"Cloning of Cellulose Synthesis Related Genes from Acetobacter xylinum ATCC23769 and ATCC53582: Comparison of Cellulose Synthetic Ability Between Strains"

- HING C. WONG*t, ANNA LISA FEAR*, ROGER D. CALHOONt, GREGORY H. EICHINGER*, RAPHAEL MAYER§, DORIT AMIKAM§, MOSHE BENZIMAN§, DAVID H. GELFAND*, JAMES H. MEADE*, ANNE W. EMERICK*, ROBERT BRUNER¶, ARIE BEN-BASSAT¶, AND RONY TAL*(Proc. Nati. Acad. Sci. USA Vol. 87, pp. 8130-8134, October 1990 Genetics)"Genetic organization of the cellulose synthase operon in Acetobacter xylinum"

- Xhavit Zogaj,1 Manfred Nimtz,2 Manfred Rohde,3 Werner Bokranz1 and Ute RoÈ mling1*(Molecular Microbiology (2001))"The multicellular morphotypes of Salmonella typhimurium and Escherichia coli produce cellulose as the second component of the extracellular matrix"

- Tetsuo Kondo(Journal of the Japan wood research society vol.54 No.3(2008))"New Developments of Cellulose nanofiber technology"

- Tetsuo Kondo(Journal of The Society of Fiber Science and Technology, Japan vol.61 No.11(2005))"Automatic construction of three-dimensional structure by microbial cellulose fiber production"

"

"