Team:UCL London/Doxycycline

From 2010.igem.org

(→Doxycycline Economic Analysis) |

|||

| Line 3: | Line 3: | ||

=Doxycycline Economic Analysis= | =Doxycycline Economic Analysis= | ||

| + | ==Doxycycline Process Flowsheet== | ||

Estimate of Doxycycline cost for an industrial scale fermentation - say 1,000L | Estimate of Doxycycline cost for an industrial scale fermentation - say 1,000L | ||

| Line 17: | Line 18: | ||

12 (gram/batch) * 32.20 ($ / gram) = $386.40 per a 1,000 batch | 12 (gram/batch) * 32.20 ($ / gram) = $386.40 per a 1,000 batch | ||

| + | [[Image:Ucl-doxylcien.png|800px|left]] | ||

==Mammalian cell process using Doxycline== | ==Mammalian cell process using Doxycline== | ||

| Line 323: | Line 325: | ||

|} | |} | ||

| - | |||

| - | |||

| - | |||

Revision as of 14:06, 27 October 2010

Doxycycline Economic Analysis

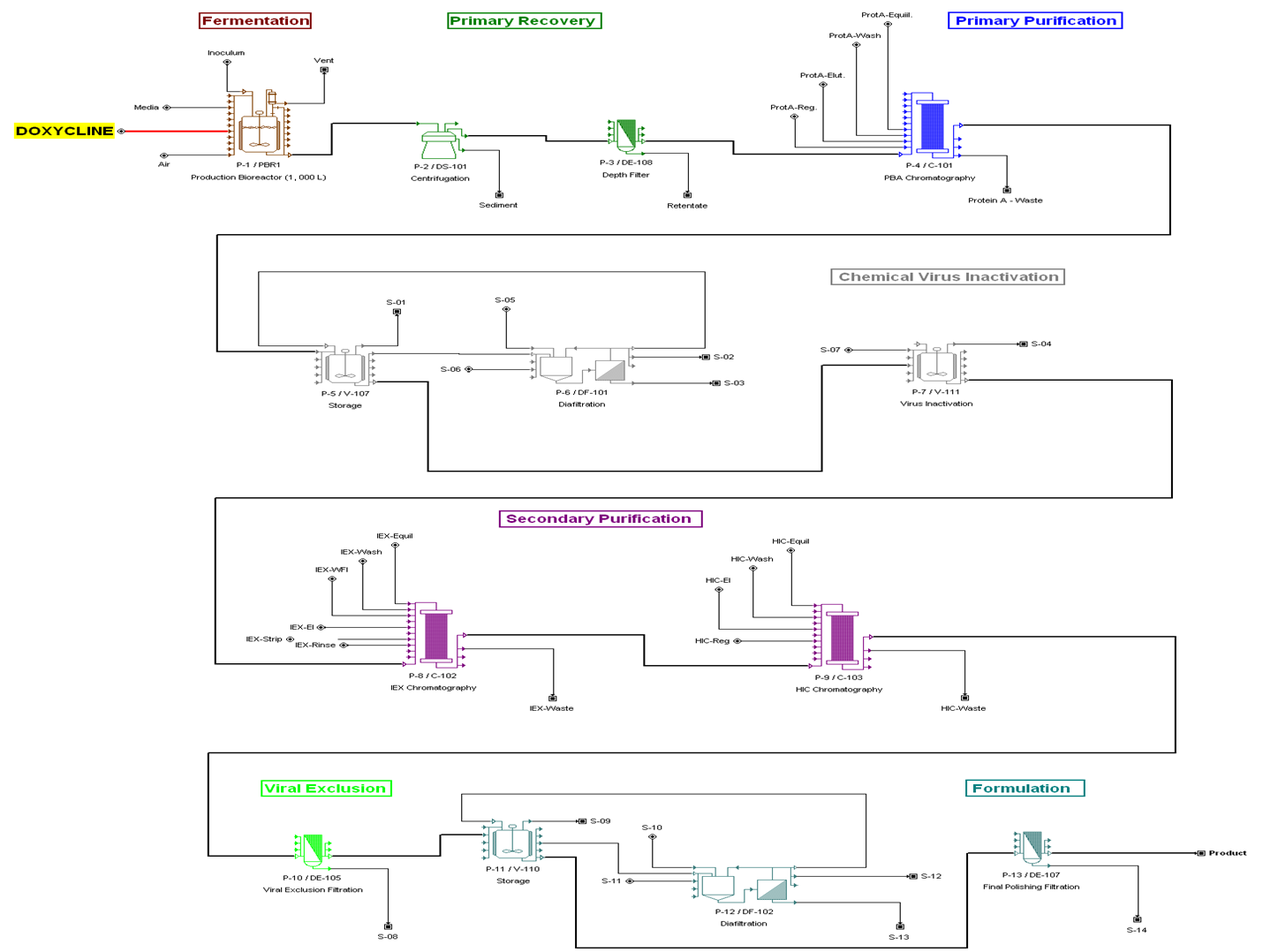

Doxycycline Process Flowsheet

Estimate of Doxycycline cost for an industrial scale fermentation - say 1,000L

I looked on Sigma Aldrich website for Doxycycline hyclate cost

• $ 32.20

• For 1 gram of Doxycycline

Finally for a 1,000 L fermentation batch, this is how much Doxycycline you need: 0.012 kg per 1,000 L batch

Cost of Doxycycline per a batch: 12 (gram/batch) * 32.20 ($ / gram) = $386.40 per a 1,000 batch

Mammalian cell process using Doxycline

| Production Volume (L) | Titre (g/L) | Product Generated (kg/batch) | Annual Production (kg/yr) | Batches (per a year) | Centrifugation Yield (%) | Filtration Yield (%) | Purification Yield (%) | Overall Yield (%) | No. Bioreactors | Scale of Bioreactors (L) |

| 40,000 | 2 | 6.3 | 132.4 | 21 | 94 | 100 | 70 | 67 | 1 | 7000 |

Note: 7,000 L fermenter example

Executive Summary

| Capital Investment ($) | 42,013,000 |

| Operating Costs ($/yr) | 16,210,726 |

| Product Unit Cost ($/kg) | 122,475 |

| Labour Cost ($/yr) | 1,805,307 |

After removing Doxycline from the production process

| ' | Before | After |

| Capital Investment ($) | 42,013,000 | 41,820,000 |

| Operating costs ($/yr) | 16,210,726 | 16,153,925 |

| Cogs ($/g) | 122.5 | 122.1 |

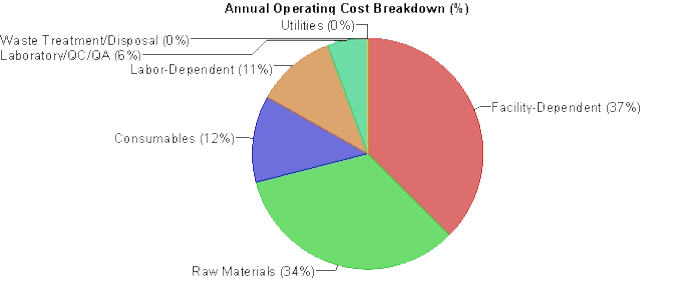

Annual Operating Cost

| Annual Operating Cost | ' | ' |

| Cost Item | $ | % |

| Raw Materials | 5,477,726 | 34 |

| Labour-Dependent | 1,805,000 | 11 |

| Facility-Dependent | 6,050,000 | 37 |

| Laboratory/QC/QA | 903,000 | 6 |

| Consumables | 1,966,000 | 12 |

| Wste Treatment/Disposable | 6,000 | 0.0 |

| Utilities | 3,000 | 0.0 |

| Total | 16,210,726 | 100 |

| Cogs ($/g) | 122.47 | |

Could this be because of Doxycline? No, doxycline makes up only 1% of the total raw material costs

Material Cost

| Material Costs | Unit Cost ($/kg) | Annual Amount (kg) | Annual Cost ($) | % |

| Media | 300 | 16 | 4,860 | 0.088722951 |

| SerumFree Media | 300 | 17,184 | 5,155,169 | 94.11148327 |

| Doxycline | 32200 | 1.764 | 56,801 | 1.03694128 |

| Water | 0 | 335 | 0 | 0 |

| WFI | 0.15 | 517,650 | 77,647 | 1.417504323 |

| Air | 0 | 88,694 | 0 | 0 |

| H3PO4 (5% w/w) | 0.14 | 121,071 | 17,253 | 0.314966478 |

| NaOH (0.5M) | 0.25 | 99,042 | 24,271 | 0.44308534 |

| Protein A Equil | 0.15 | 144,251 | 22,063 | 0.402776641 |

| Protein A Eluti | 0.15 | 65,347 | 10,029 | 0.18308693 |

| Prot- A Reg Buffer | 0.17 | 39,230 | 6,580 | 0.120122844 |

| NaOH (0.1M) | 0.24 | 135,799 | 33,015 | 0.60271363 |

| IEX -Eq-Buffer | 0.19 | 21,491 | 4,000 | 0.073023005 |

| IEX-Wash-Buffer | 0.22 | 21,586 | 4,766 | 0.087006911 |

| IEX-El-Buffer | 0.35 | 1,217 | 423 | 0.007722183 |

| NaCl (1M) | 0.37 | 13,196 | 4,860 | 0.088722951 |

| Amm. Sulfate | 8 | 919 | 7,354 | 0.134252795 |

| HIC-Eq-Buffer | 0.91 | 8,522 | 7,744 | 0.141372538 |

| HIC-Wash-Buffer | 0.54 | 20,256 | 10,898 | 0.198951178 |

| HIC-El-Buffer | 0.31 | 19,645 | 5,985 | 0.109260672 |

| NaOH (1M) | 0.34 | 65,709 | 22,094 | 0.40334257 |

| PBS | 0.18 | 15,255 | 1,913 | 0.034923252 |

| Polysorbate 80 | 1.83 | 1 | 1 | 1.82558E-05 |

| Total | - | 5,477,726 | 100 | |

Consumable Costs

| Consumable Costs | Unit Cost ($) | Annual Amount | Annual Cost ($) |

| Dft DEF Cartridge | 1,000 | 63 | 63,000 |

| Dft Membrane | 400 | 10 m2 | 4,008 |

| 50 L Bag | 5 | 210 | 1,050 |

| Viral Exclusion Membrane | 13,356 | 21 | 280,476 |

| Protein A | 6,000 | 167 L | 1,000,337 |

| SP-Sepharose High Performance | 1,200 | 98 L | 117,915 |

| HIC Butyl Sepharose High Performance | 2,050 | 9 L | 18,332 |

| Total | - | - | 1,485,118 |

Equipment Cost $

Doxycline is added from a holding tank, absence of doxycline will make minimal difference to USP costs.

DSP costs are very high, that a cost reduction in the USP section has no significant difference to the total equipment costs

| USP | DSP | Total Cost | USP:DSP |

| 732,000 | 2,607,000 | 3,339,000 | 0.28 |

| USP | ' | ' |

| Equipment Name | Cost ($) | |

| Stirred tank reactor | 539,000 | |

| Blending Tank | 193,000 | |

| DSP | ||

| Blending Tank | 191,000 | |

| Blending Tank | 159,000 | |

| Diafilter | 26,000 | |

| Chromatography Column | 148,000 | |

| Blending Tank | 137,000 | |

| Chromatography Column | 144,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 134,000 | |

| Diafilter | 22,000 | |

| Dead-End Filter | 32,000 | |

| Disposable Container-Skid | 0 | |

| Disk-Stack Centrifuge | 370,000 | Most expensive piece of equipment downstream |

| Dead-End Filter | 32,000 | |

| Chromatography Column | 192,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 134,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 127,000 | |

| Dead-End Filter | 32,000 | |

| Unlisted Equipment | 677,000 | |

| Total | 3,385,000 | |

Waste Treatment/Disposal Cost

Waste disposal costs are mainly for CEX and HIC

| Waste Category | Unit Cost ($/kg) | Annual Amount (kg) | Annual Cost ($) | % |

| Solid Waste | - | 0 | 0 | 0 |

| Aqueous Liquid | - | 156,691 | 6,268 | 100 |

| IEX - Waste | 0.04 | 87,190 | 3,488 | 55.64 |

| HIC- Waste | 0.04 | 69,500 | 2,780 | 44.36 |

| Organic Liquid | - | 0 | 0 | 0 |

| Emissions | - | 88,584 | 0 | 0 |

| Total | - | 245,275 | 6,268 | 100 |

Throughput Analysis

On SuperPro it assumes it would take 60 minutes to set up the Doxycline inlet This is 0.3 % of the overall process, delay in set up doesn't have a profound effect.

| Process Data | ' | ' |

| Annual Operating time | 7,104.66 | Hours |

| Annual Throughput | 132.36 | Kg/MP |

| Batch Throughput | 6.3 | Kg/MP |

| Plant Batch Time | 397.49 | Hours |

| Number of Batches per a year | 21 | Batches |

| Time Bottleneck Equipment | Production Fermenter | PBR1 |

| Throughput Utilization | 90 | % |

"

"

Twitter

Twitter Facebook

Facebook UCL

UCL Flickr

Flickr YouTube

YouTube