Team:UCL London/Future Vision

From 2010.igem.org

(→Online/Real time monitoring) |

|||

| Line 29: | Line 29: | ||

==Online/Real time monitoring== | ==Online/Real time monitoring== | ||

| - | Green | + | [[Image:UCL-Green.JPG||300px|right]] |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| + | The current method of monitoring the dissolved oxygen in a fermenter is placing several dissolved oxygen probes in different locations of the fermenter. Using the green dye gene, we can reduce the number of probes needed, and depend on a more "live" visual technique! | ||

{{:Team:UCL_London/templates/v2/footerFullWidth}} | {{:Team:UCL_London/templates/v2/footerFullWidth}} | ||

Revision as of 23:15, 10 October 2010

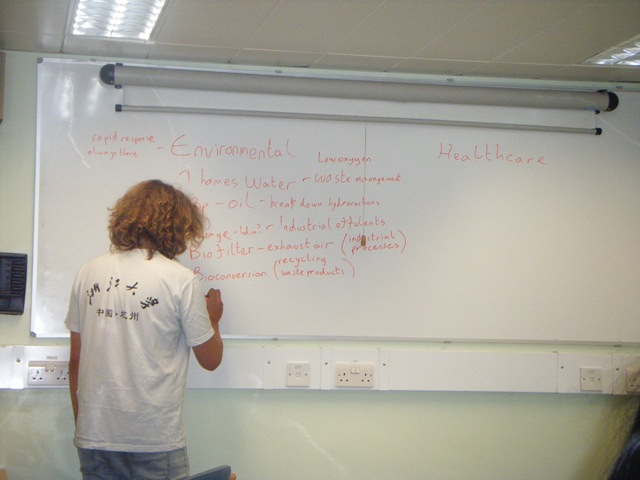

FUTURE VISION

At this stage, our main aim is to show that our circuit does in fact react in the way it does to hypoxia. Pending this achievable target, we have high hopes of our Principle being implemented in a potentially infinite number of ways. We have split them into the following main categories just to give you an idea.

Health & Medicine

Imagine if the bacteria as we know it today could drive protein expression with the lack of oxygen. Synthetic biology through biochemical engineering can create the potential at which Escherichia coli cells- and we all know how harmful to humans can specific strains be- used in a twisted yet beautifully way as an expression system for the production of biopharmaceuticals. The project is based on the engineering modification of the cells and the construction of a self-induced biological circuit that allows an automated protein expression

Manufacturing

We all remember the Swine flu pandemic outbreak? About a year ago. The production of such a great amount of pharmaceuticals in such a short time to cover the needs of x people, was only based on a well planned engineering scale-up equations and an established protocol. Therefore, in order to create a product and with regards to our project, a pharmaceutical drug, there is the need to establish the conditions that will enable the effective development of the process and the efficient and most economically viable product. By decreasing the cost of the project, it only means that it is delivered to the patient at a lower cost. By producing more naturally occurring drugs, avoiding as much as possible chemicals that can cause damage to the cells or side-effects of the tablet, meaning that a safer product has been manufactured and is ready for consumption.

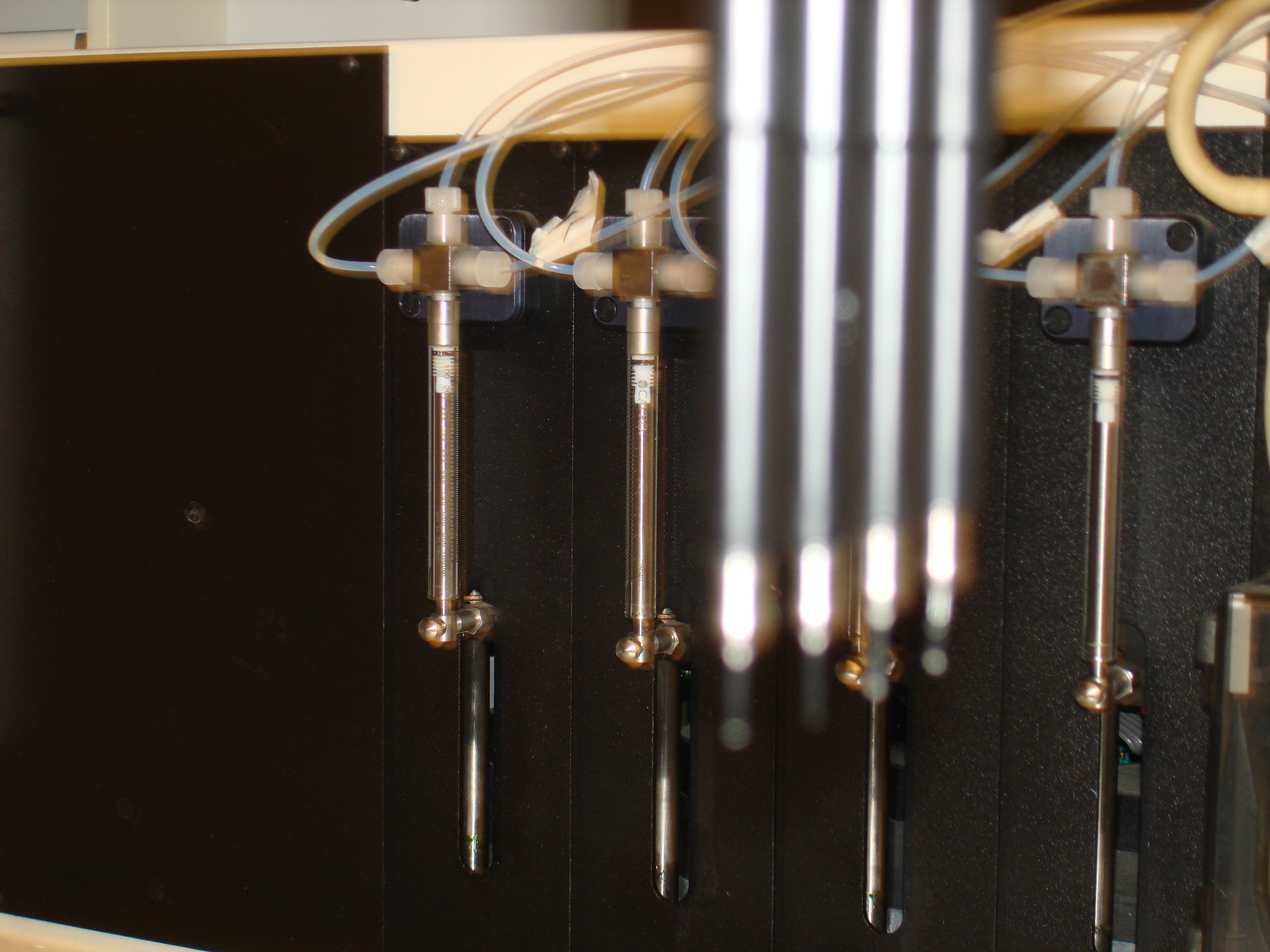

Online/Real time monitoring

The current method of monitoring the dissolved oxygen in a fermenter is placing several dissolved oxygen probes in different locations of the fermenter. Using the green dye gene, we can reduce the number of probes needed, and depend on a more "live" visual technique!

"

"

Twitter

Twitter Facebook

Facebook UCL

UCL Flickr

Flickr YouTube

YouTube