Team:UCL London/Health & Safety Analysis

From 2010.igem.org

(→Hazard and Operability Study – Fermentation) |

(→Hazard and Operability Study – Fermentation) |

||

| Line 50: | Line 50: | ||

[[Image:ucl-arrows2.png|800px|center]] | [[Image:ucl-arrows2.png|800px|center]] | ||

| + | Fig. 2 Components of the fermentation control scheme (Montague, 1997) | ||

{{:Team:UCL_London/templates/v2/footerFullWidth}} | {{:Team:UCL_London/templates/v2/footerFullWidth}} | ||

Revision as of 17:20, 24 October 2010

Health & Safety Analysis

A deeper approach was adopted by attending a safety training run by the Department of Biochemical Engineering at University College London, in order to know "the code of practice". An initial Hazard identification and assessment was carried as a first step, which included the identification of any compound-from ionised water, to buffers, to GMOs (Genetically Modified Organisms) and the assessment of the risk they imposed upon human health.

The critically of Health & Safety, under the Health & Safety at Work Act 1974, was emphasised and bear in mind at all times, as this is "the alpha and the omega" meaning that any professional research should be carried under the regulations published by the relevant regulatory bodies, for the health and safety of the researchers. HSE, the Health and Safety Executive in UK, is the main regulatory body providing the relevant advice and support for any industrial business. With regards to our case, we made quite a breadth and depth research into the policy surrounding the operation of a pharmaceutical industry plant and summarised some key points:

Process Validation Process validation allows understanding and control of the process, equipment and facility. QC testing After the process is validated, each batch is then validated via QC testing for Purity, potency and sterility

GMP, GLP and GCP compliance A biopharmaceutical facility must comply with the GMP, GLP, GCP requirements: General Manufacturing/Laboratory/Clinical Practices respectively, by the FDA (Food and Drug Administration) Design Qualification of equipment (DQ) Installation Qualification of systems (IQ) Operational Qualification (OQ) Process Qualification (PQ)

Accident Prevention Policy & Emergency plans Emergency procedures must be in place e.g. In case of a fire: according to the 1910(29 CFR) Subpart E (OSHA) Occupational Safety and Health Administration of the United States: Exit routes, emergency evacuation plans, first aid facilities, breathing apparatus and of course trained personnel. Staff training For example, operators risk injury from lifting and handling heavy machinery or from repetitive strain problems. This is very important, as taking breaks as often as required from daunting tasks, is within the employee's rights.

Hazard identification and assessment For example Oxygen: the dangers are fire and explosion (HSE, 2006), detergents e.g. ethanol: flammable liquid, caustic and potential carcinogen (J.T. Baker, 2006). Documentation SOP: Standard operating procedure, BMR: batch manufacturing record, records of process data and monitoring data.

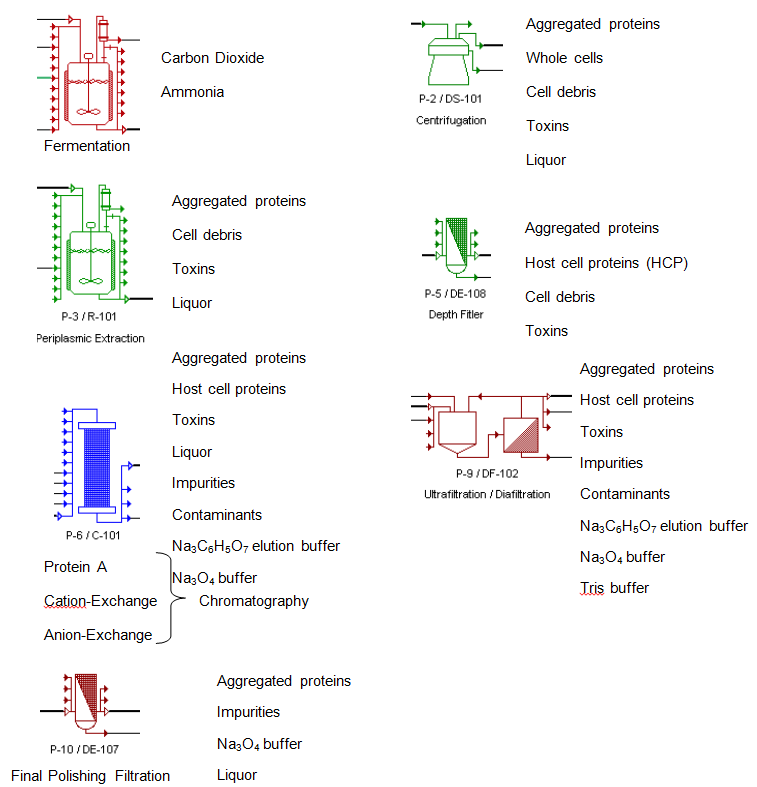

Mechanical Integrity Critical when operating highly pressurised equipment such as a highly packed chromatography column, a centrifuge or other unit operations. Regular checking and maintenance is required. Waste Management Waste handling is a way of improving efficiency on the production plan as well as maximizing profits. Protein aggregation, contaminants, toxins, host cell proteins, cell debris, lipids and other by-products liquid/solid/gas must be identified and follow the suitable pre-treatment route. Waste Stream Components

Hazard and Operability Study – Fermentation

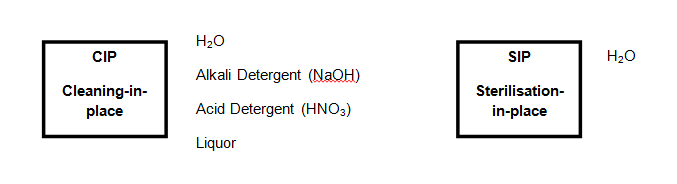

The Hazard and operability study should be applied to all new designs (Kletz, 1999). However, if there is an obvious major hazard then the hazard analysis should be carried out. Hazop and Hazan methods are often confused but their differences are clearly distinguished.

The Hazop technique was developed in 1963 by the Heavy Organic Chemicals (HOC) Division of ICI. It is the preferred technique used on every project for identifying hazards. It is a qualitative method and is usually done by a team so as people can built upon each other’s ideas. Sometimes is also called ‘what if’ method since it provides the opportunity for the members of the team to think of all the possible ways in which a hazard or operating problem may be caused. Therefore Hazop reduces the chance of something to go wrong and hence each pipeline should be considered. The Hazan is a selective technique since it is used whenever there is the need, the data and the resources to attempt to quantify every problem on every plant. In the U.S. this technique is called ‘quantitative risk assessment’ QRA since it assess or quantifies hazards. It tells the size of a risk and especially when fault trees are used it shows how the hazards arise, which factors contributed to the most and what are the effective solutions of reducing the risk.

The above fugure shows the methods for identifying and assessing hazards. It is a re-production from Kletz Trevor’s ‘Hazop and Hazan’ book.

Despite though the efforts made to eliminate the occurrence of hazards to zero it is impossible; we shall fail to foresee every hazard and some will result in accidents. Usually simple solutions give fewer problems. The standard form for Hazop Management is by recording results, issuing of actions, receiving responses while software programs like HAZOP Manager- Lihou can be used as an aid in Hazop studies. Usually a Hazop study, as mentioned above, is carried out by a team that is comprised by: a project or design engineer (PE/DE), a process engineer, a commissioning manager (CM), the control system design engineer, the Instrument design engineer (IDE), the Independent Team Leader (IC) or Secretary and a research chemist/ specialist scientist.

The Hazop properties that are examined are the flow, pressure, level, temperature, quality, and chemical reaction etc of a section of the system. In this study fermentation is the main focus section. Guide words like: NO, MORE, LESS, REVERSE, PART (composition), EXTRA, RELIEF (back up guide word) are used (Kletz, 1999), the deviation and the possible causes for the different events are defined and the evaluation of the consequences as well as recommended actions are recorded in a table. For this HAZOP study 2 nodes were selected to be examined. The selection of each ‘node’ for the HAZOP study was based on the later method of assigning nodes (PHA, 2004). Therefore a single node comprised by a feed piping from the fermenter, a pump, valves and a heat exchanger is treated as a single or as it is known a compound node. This method was chosen against the early one that each line entering a vessel was treated as a separate node since it was found that there is less repeating, greater progress and more efficient HAZOPs.

Fig. 2 Components of the fermentation control scheme (Montague, 1997)

"

"

Twitter

Twitter Facebook

Facebook UCL

UCL Flickr

Flickr YouTube

YouTube