Team:UCL London/Doxycycline

From 2010.igem.org

Doxycycline Economic Analysis

Doxycycline Biorocess Flowsheet

Cost

Estimate of Doxycycline cost for an industrial scale fermentation based on the 1,000L mammalian cell model

From Sigma Aldrich website for Doxycycline hyclate cost is $ 32.20 for 1 gram of Doxycycline

Finally for a 1,000 L fermentation batch, this is how much Doxycycline you need is 0.012 kg per 1,000 L batch

Cost of Doxycycline per a batch: 12 (gram/batch) * 32.20 ($ / gram) = $386.40 per a 1,000 batch

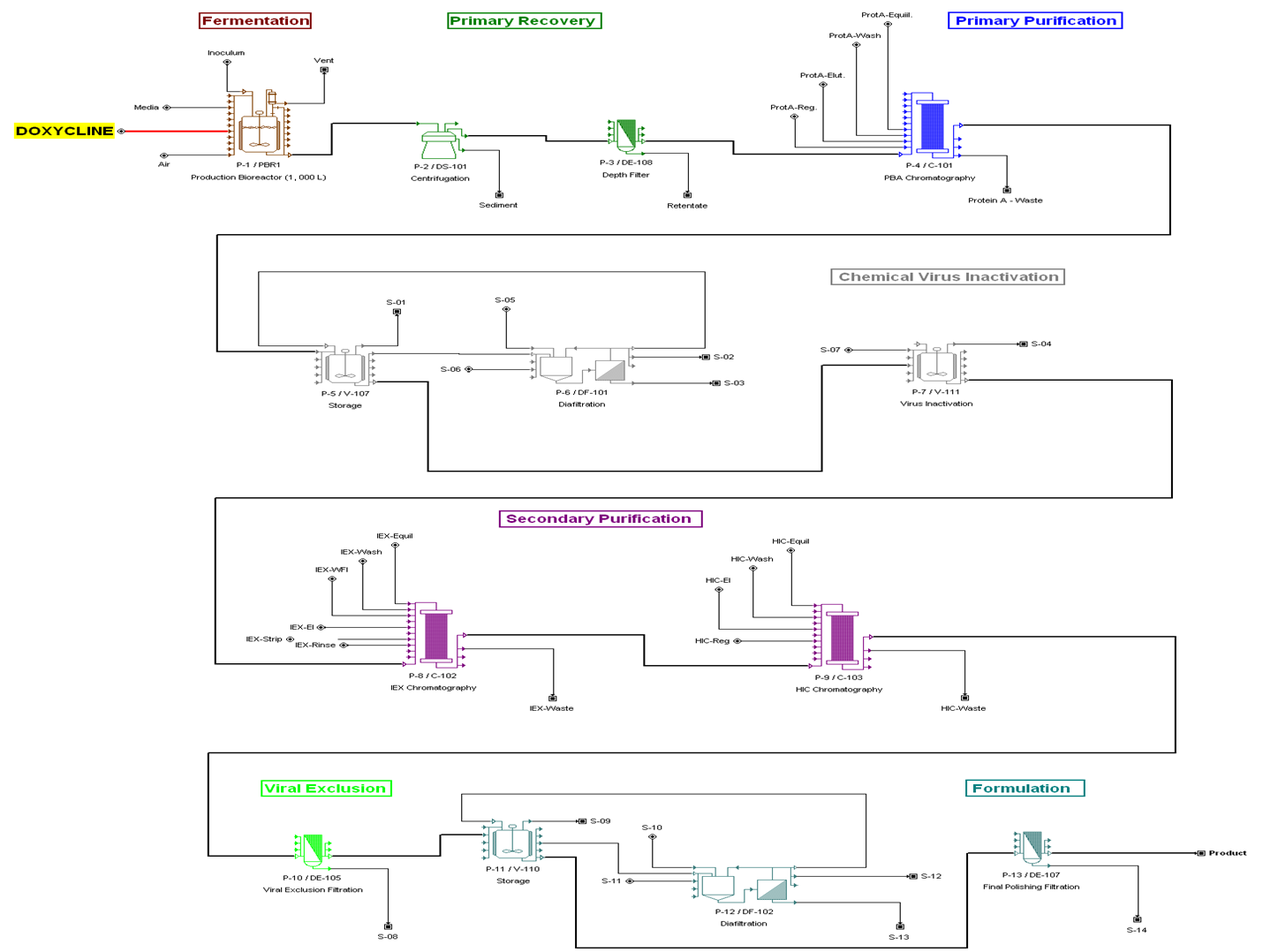

Bioprocess Flowsheet

A bioprocess flowsheet was constructed with regards to the mammalian cell system, in order to define all the necessary upstream and downstream steps and assess whether this choice is a feasible one.

The main steps for the antibody production expressed in mammalian cell culture are the primary recovery, primary purification, viral inactivation, secondary purification and viral exclusion prior to formulation, as indicated by the following SuperPro flowsheet.

Mammalian cell process using Doxycline

| Production Volume (L) | Titre (g/L) | Product Generated (kg/batch) | Annual Production (kg/yr) | Batches (per a year) | Centrifugation Yield (%) | Filtration Yield (%) | Purification Yield (%) | Overall Yield (%) | No. Bioreactors | Scale of Bioreactors (L) |

| 40,000 | 2 | 6.3 | 132.4 | 21 | 94 | 100 | 70 | 67 | 1 | 7000 |

Note: 7,000 L fermenter example

Executive Summary

| Capital Investment ($) | 42,013,000 |

| Operating Costs ($/yr) | 16,210,726 |

| Product Unit Cost ($/kg) | 122,475 |

| Labour Cost ($/yr) | 1,805,307 |

After removing Doxycline from the production process

| ' | Before | After |

| Capital Investment ($) | 42,013,000 | 41,820,000 |

| Operating costs ($/yr) | 16,210,726 | 16,153,925 |

| Cogs ($/g) | 122.5 | 122.1 |

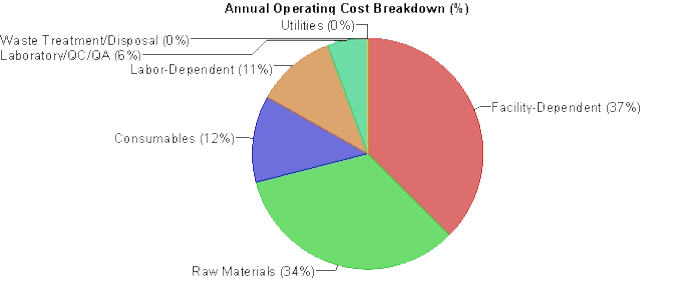

Annual Operating Cost

| Annual Operating Cost | ' | ' |

| Cost Item | $ | % |

| Raw Materials | 5,477,726 | 34 |

| Labour-Dependent | 1,805,000 | 11 |

| Facility-Dependent | 6,050,000 | 37 |

| Laboratory/QC/QA | 903,000 | 6 |

| Consumables | 1,966,000 | 12 |

| Wste Treatment/Disposable | 6,000 | 0.0 |

| Utilities | 3,000 | 0.0 |

| Total | 16,210,726 | 100 |

| Cogs ($/g) | 122.47 | |

Could this be because of Doxycline? No, doxycline makes up only 1% of the total raw material costs

Material Cost

| Material Costs | Unit Cost ($/kg) | Annual Amount (kg) | Annual Cost ($) | % |

| Media | 300 | 16 | 4,860 | 0.088722951 |

| SerumFree Media | 300 | 17,184 | 5,155,169 | 94.11148327 |

| Doxycline | 32200 | 1.764 | 56,801 | 1.03694128 |

| Water | 0 | 335 | 0 | 0 |

| WFI | 0.15 | 517,650 | 77,647 | 1.417504323 |

| Air | 0 | 88,694 | 0 | 0 |

| H3PO4 (5% w/w) | 0.14 | 121,071 | 17,253 | 0.314966478 |

| NaOH (0.5M) | 0.25 | 99,042 | 24,271 | 0.44308534 |

| Protein A Equil | 0.15 | 144,251 | 22,063 | 0.402776641 |

| Protein A Eluti | 0.15 | 65,347 | 10,029 | 0.18308693 |

| Prot- A Reg Buffer | 0.17 | 39,230 | 6,580 | 0.120122844 |

| NaOH (0.1M) | 0.24 | 135,799 | 33,015 | 0.60271363 |

| IEX -Eq-Buffer | 0.19 | 21,491 | 4,000 | 0.073023005 |

| IEX-Wash-Buffer | 0.22 | 21,586 | 4,766 | 0.087006911 |

| IEX-El-Buffer | 0.35 | 1,217 | 423 | 0.007722183 |

| NaCl (1M) | 0.37 | 13,196 | 4,860 | 0.088722951 |

| Amm. Sulfate | 8 | 919 | 7,354 | 0.134252795 |

| HIC-Eq-Buffer | 0.91 | 8,522 | 7,744 | 0.141372538 |

| HIC-Wash-Buffer | 0.54 | 20,256 | 10,898 | 0.198951178 |

| HIC-El-Buffer | 0.31 | 19,645 | 5,985 | 0.109260672 |

| NaOH (1M) | 0.34 | 65,709 | 22,094 | 0.40334257 |

| PBS | 0.18 | 15,255 | 1,913 | 0.034923252 |

| Polysorbate 80 | 1.83 | 1 | 1 | 1.82558E-05 |

| Total | - | 5,477,726 | 100 | |

Consumable Costs

| Consumable Costs | Unit Cost ($) | Annual Amount | Annual Cost ($) |

| Dft DEF Cartridge | 1,000 | 63 | 63,000 |

| Dft Membrane | 400 | 10 m2 | 4,008 |

| 50 L Bag | 5 | 210 | 1,050 |

| Viral Exclusion Membrane | 13,356 | 21 | 280,476 |

| Protein A | 6,000 | 167 L | 1,000,337 |

| SP-Sepharose High Performance | 1,200 | 98 L | 117,915 |

| HIC Butyl Sepharose High Performance | 2,050 | 9 L | 18,332 |

| Total | - | - | 1,485,118 |

Equipment Cost $

Doxycline is added from a holding tank, absence of doxycline will make minimal difference to USP costs.

DSP costs are very high, that a cost reduction in the USP section has no significant difference to the total equipment costs

| USP | DSP | Total Cost | USP:DSP |

| 732,000 | 2,607,000 | 3,339,000 | 0.28 |

| USP | ' | ' |

| Equipment Name | Cost ($) | |

| Stirred tank reactor | 539,000 | |

| Blending Tank | 193,000 | |

| DSP | ||

| Blending Tank | 191,000 | |

| Blending Tank | 159,000 | |

| Diafilter | 26,000 | |

| Chromatography Column | 148,000 | |

| Blending Tank | 137,000 | |

| Chromatography Column | 144,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 134,000 | |

| Diafilter | 22,000 | |

| Dead-End Filter | 32,000 | |

| Disposable Container-Skid | 0 | |

| Disk-Stack Centrifuge | 370,000 | Most expensive piece of equipment downstream |

| Dead-End Filter | 32,000 | |

| Chromatography Column | 192,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 134,000 | |

| Dead-End Filter | 32,000 | |

| Blending Tank | 127,000 | |

| Dead-End Filter | 32,000 | |

| Unlisted Equipment | 677,000 | |

| Total | 3,385,000 | |

Waste Treatment/Disposal Cost

Waste disposal costs are mainly for CEX and HIC

| Waste Category | Unit Cost ($/kg) | Annual Amount (kg) | Annual Cost ($) | % |

| Solid Waste | - | 0 | 0 | 0 |

| Aqueous Liquid | - | 156,691 | 6,268 | 100 |

| IEX - Waste | 0.04 | 87,190 | 3,488 | 55.64 |

| HIC- Waste | 0.04 | 69,500 | 2,780 | 44.36 |

| Organic Liquid | - | 0 | 0 | 0 |

| Emissions | - | 88,584 | 0 | 0 |

| Total | - | 245,275 | 6,268 | 100 |

Throughput Analysis

On SuperPro it assumes it would take 60 minutes to set up the Doxycline inlet This is 0.3 % of the overall process, delay in set up doesn't have a profound effect.

| Process Data | ' | ' |

| Annual Operating time | 7,104.66 | Hours |

| Annual Throughput | 132.36 | Kg/MP |

| Batch Throughput | 6.3 | Kg/MP |

| Plant Batch Time | 397.49 | Hours |

| Number of Batches per a year | 21 | Batches |

| Time Bottleneck Equipment | Production Fermenter | PBR1 |

| Throughput Utilization | 90 | % |

"

"

Twitter

Twitter Facebook

Facebook UCL

UCL Flickr

Flickr YouTube

YouTube