Team:TU Delft/Project/alkane-degradation/results

From 2010.igem.org

Alkane Degradation Results & Conclusions

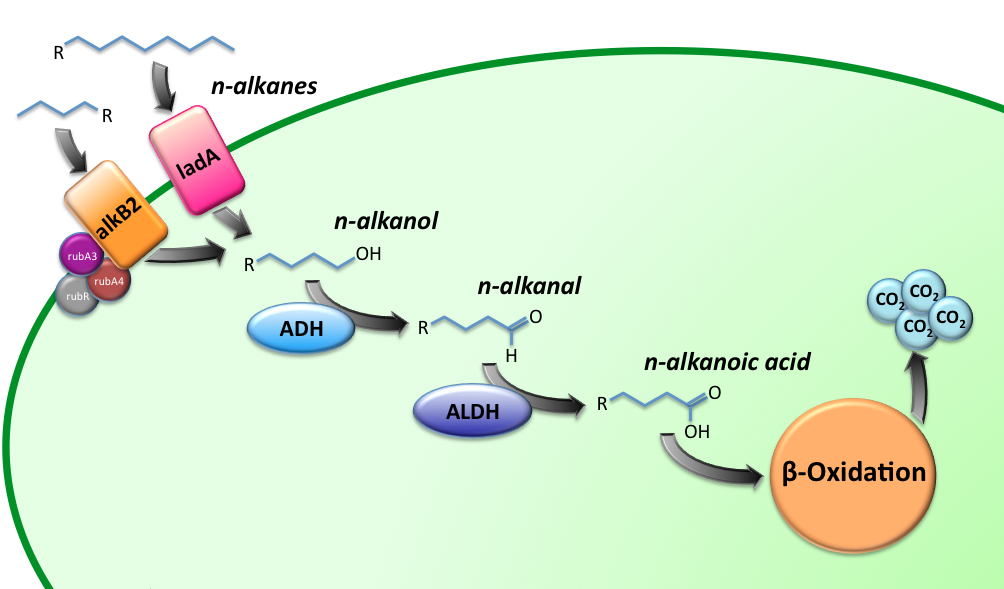

Characterization of the alkane hydroxylase system

Growth analysis

We attempted to culture our recombinant AH-carrying E.coli K12 strains ([http://partsregistry.org/Part:BBa_K398014 BBa_K398014]) on 1% v/v octanol or 1% v/v dodecane. Negligible growth was observed.

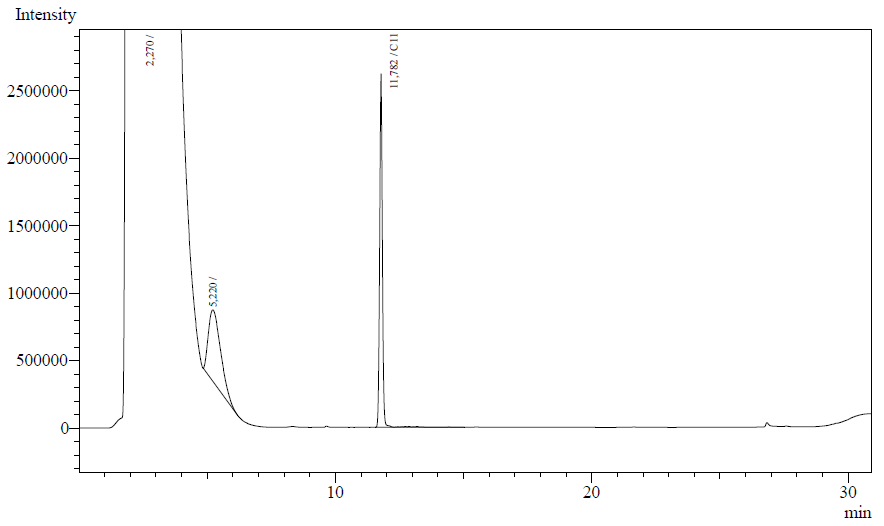

Resting-cell assays

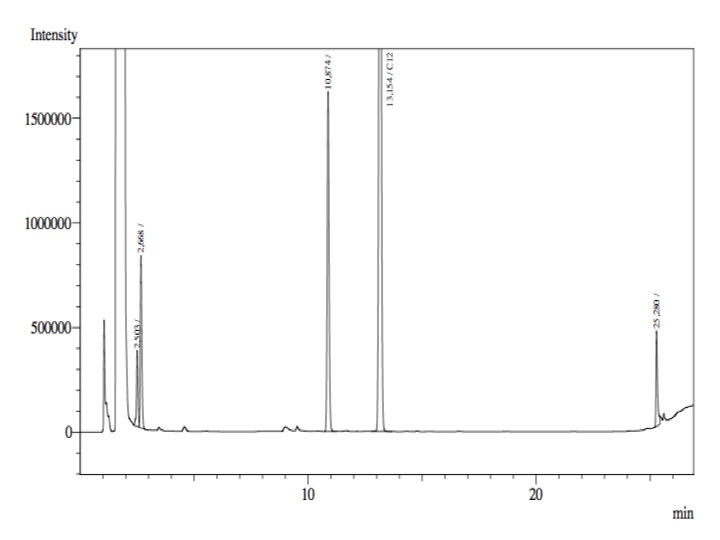

The resting cell assays were performed on our recombinant AH-carrying E.coli K12 cells ([http://partsregistry.org/Part:BBa_K398014 BBa_K398014]). 100 micromoles of octane was added to 6 mL of growth-stalled cells (1.5 mg cell dry weight total) and incubated at 37 degrees with shaking o/n. The organic phase was extracted using EtOAc and analysed by gas chromatography.

The following chromatographs were obtained:

LadA

Alcohol DeHydrogenase (ADH) system

= Results

Growth on alcohols as sole carbon source

- As we described before, we tried to grow our strain Escherichia coli 018A (Biobrick BBa_K398018 on the plasmid pSB1A2) on the alkanols Octanol-1 and Dodecanol-1. No growth was observed after 48 hours. We abandoned this experiment after this result.

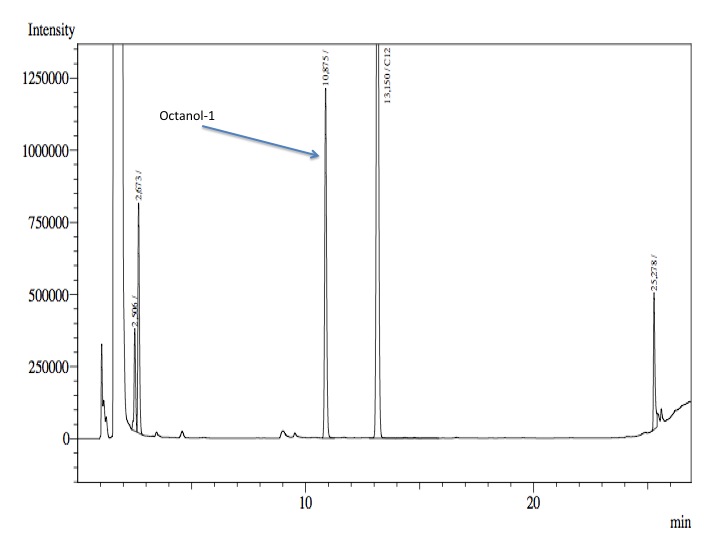

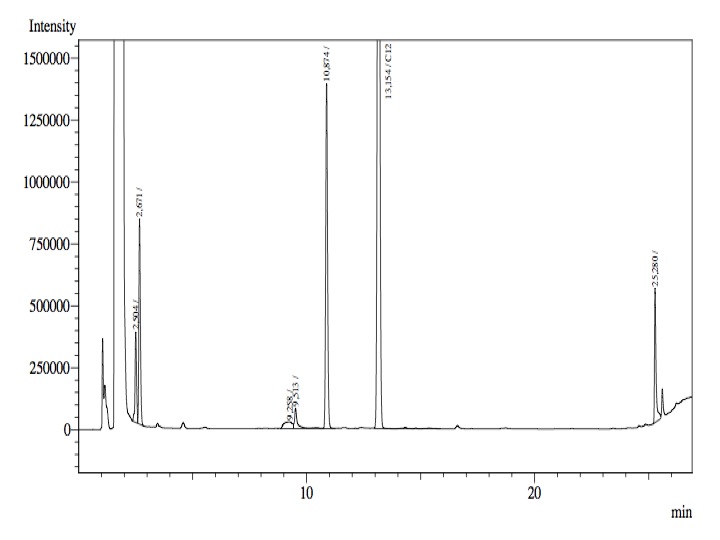

Resting cell assays

- We grew Escherichia coli 018A and Escherichia coli negative control (Biobrick BBa_J13002 on plasmid pSB1A2 ) in 50 mL of M9 medium with glucose and CAS aminoacids.

| Strain | O.D. |

| J13002 | 0.327 |

| 018A | 0.338 |

- The cells were harevested when the O.D. at 600nm was around 0.3; they were spun down at 4000 rpm, for 10 min at 4ºC.

- The pellet was resuspended in 5 mL of phosphate buffer with glucose and salts. This was a washing step, then the cells were spun down again (same conditions) and resuspended in the same amount of phosphate buffer.

- Finally, from the cellular suspension it was used 1 mL; 4 mL of fresh phosphate buffer with glucose and salts were added and 100 nmol of Octanol-1.

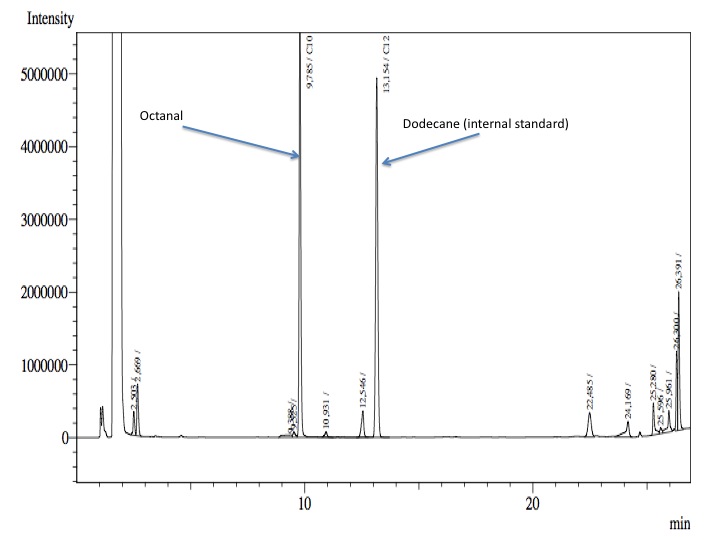

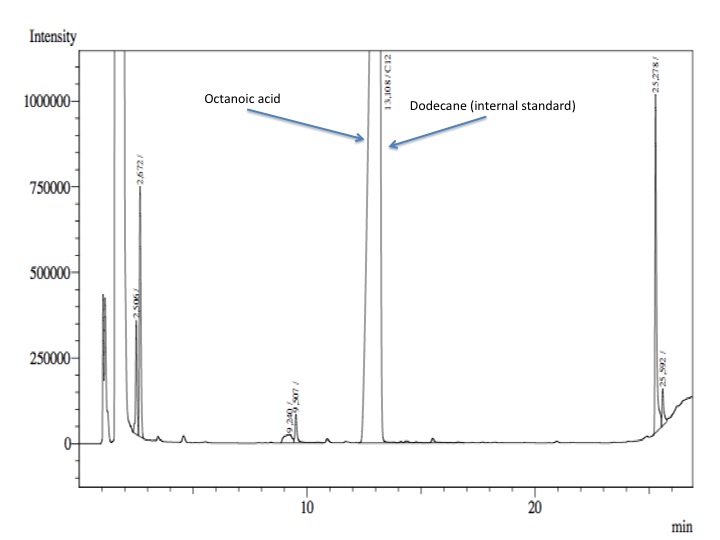

- After an overnight incubation at 37ºC, the organic phase was extracted using 3 mL of ethyl acetate (dodecane was used as internal standard). We tried to determine production of alkanals or alkanoic acids by Gas Chromatography measurements. The chromatograms are shown below:

- According to our results there was no degradation of octanol-1 ='( , after this experiment the protocol was abandoned. We think that the cells lack of transporters for long-chain alcohols, we preferred to check the cell extract in order to know if there was any biological activity in the cytoplasma.

NADH production in cell extracts

- Cells were cultured in 50mL of LB medium and harvested when the O.D. 600nm of the culture was around 0.6. Two different cultures of the recominant strain and the negative control were prepared.

| Strain | O.D. 600nm |

| J13002 (1) | 0.654 |

| J13002 (2) | 0.621 |

| 018A (1) | 0.615 |

| 018A (2) | 0.580 |

- Cytoplasmic proteins were extracted using our standard protocol.

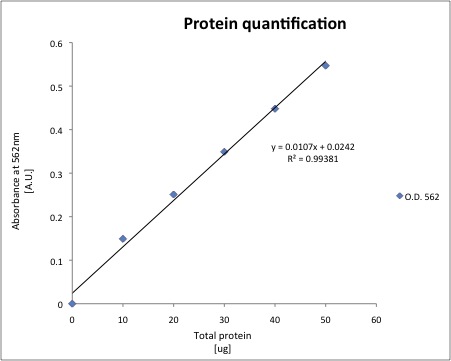

- A standard curve for protein quantification was prepared.

- The total protein of each sample was quantified using 20uL of cell extract, the results are shown below.

| Sample | O.D. 562 nm | Total ug of protein | ug/uL |

| J13002(1A) | 0.135 | 10.393 | 1.0393 |

| J13002 (1B) | 0.135 | 10.393 | 1.0393 |

| J13002 (2A) | 0.128 | 9.7363 | 0.9736 |

| J13002 (2B) | 0.129 | 9.8302 | 0.9830 |

| 018A (1A) | 0.097 | 6.8275 | 0.6827 |

| 018A (1B) | 0.091 | 6.2645 | 0.6264 |

| 018A (2A) | 0.092 | 6.3583 | 0.6358 |

| 018A (2B) | 0.092 | 6.3583 | 0.6358 |

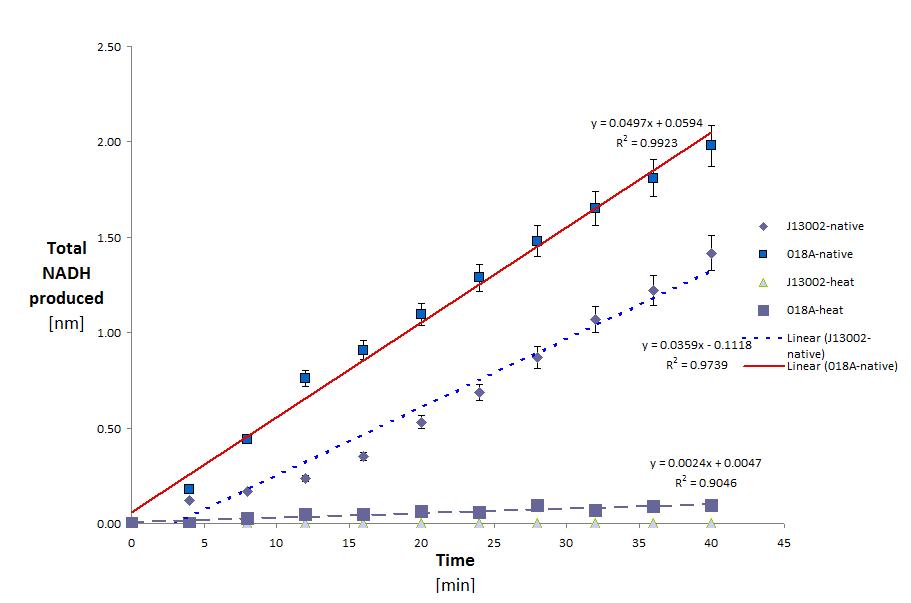

- The alcohol dehydrogenase activity was measured using the standard protocol and Dodecanol-1 as substrate. You can download our raw data by clicking on the link: File:TUDelft ADH raw.xls

ADH was tested with Dodecanol (C12)

This yielded the following results:

| Conditions | Native | Native | Heated | Heated |

| Sample | J13002 | K398018 | J13002 | K398018 |

| Total protein in well | 3.303E-02 | 3.180E-02 | 7.351E-03 | 7.994E-03 |

| Specific activity (kat/mg) | 1.812E-11 | 2.606E-11 | 0.000E-00 | 5.041E-12 |

Conclusions

This shows two things. That E.Coli is partly able to degrade Dodecanol on it's own. And that this activity is greatly increased (43.83% normalized for the amount of protein) with the addition of the ADH gene. It is also clear that eventhough ADH is from a thermophilic organism it loses most (63.5%) of it's activity after heating. the raw data for these calculations can be seen below. (Although this decrease in activity could also be attributed to the host organism lacking the proper post translational modifications.)

ALDH

Growth on alcohols as sole carbon source

As in the case of alkane monooxygenases, our first attempt was to grow our recombinant strains on long-chain alcohols and aldehydes; hoping that E. coli will do the further degradation steps. For that purpose, we used octanol-1 and dodecanol-1 for the ADH system; whereas we used octanal and dodecanal for the ALDH system. If everything goes well, we should see microbial growth on minimal medium with these compounds as sole carbon source.

Resting cell assays

Our second attempt was to grow cells, until the exponential phase is reached; then the cells were collected and the spent medium was changed for a buffer with glucose that lacked of N-source, this was done in order to avoid more biomass production. Additionally we added alcohols and aldehydes to the mixture, so that if our part is working they will be converted in other molecules: alcohols to aldehydes and aldehydes to alkanoic acids.

With this approach, we are hoping that the enzymes produced during the growth phase will remain inside the cells. The glucose added will serve for maintenance purposes and co-factor regeneration. If everything works well, there will be some nice peaks appearing on our GC analysis.

NADH production in cell extracts

We called this assay: THE LAST RESOURCE =s

Basically, we grew cells until an O.D. (600nm) between 0.5-1.0. We needed chubby healthy happy exponential-growth cells because most of our constructions are meant for protein production in this growth phase.

Once, we got a lot of cells... we disrupted them by sonication and we analyze the NADH production by their guts using a simple spectrophotometrical analysis. If our parts are working, we should see a higher NADH production when the substrate (dodecanol-1 or dodecanal) to the buffer with microbial guts and NAD buffer. We can use this method because NAD is the natural co-factor of our proteins. Fortunately for us, NAD reduction could be easily quantified by absorbance measurements at 340 nm.

We called this protocol "the last resource" because the others didn't work. Which means that alcohols and aldehydes do not cross the cell membrane, thus in order to grow cell on these compounds as sole carbon sources... WE NEEDED TO ADD TRANSPORTERS =(

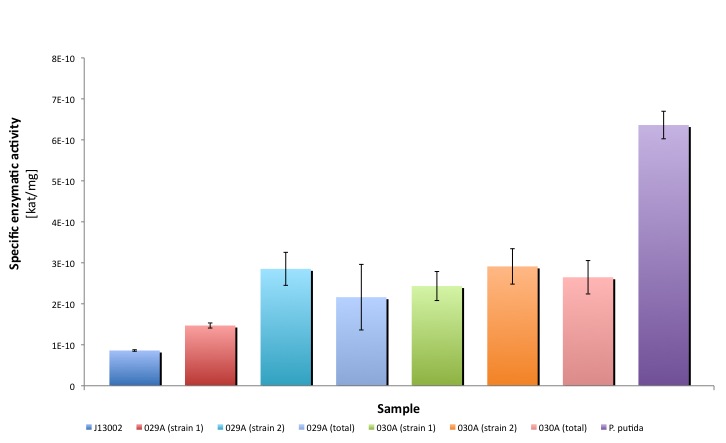

BBa_K398030 and BBa_K398029

Both Biobricks are the protein generators of Bt-ALDH. We compared the activities of bot parts, parental strain with an empty plasmid (J13002) and a natural oil-degrader (Pseudomonas putida).

View [http://partsregistry.org/wiki/index.php?title=Part:BBa_K398029 BBa_K398029 in the parts registry]

Specified Components <partinfo>K398029 SpecifiedComponents</partinfo>

Designer: <partinfo>K398029 Designer</partinfo>

Status: <partinfo>K398029 Status</partinfo>

View [http://partsregistry.org/wiki/index.php?title=Part:BBa_K398030 BBa_K398030 in the parts registry]

Specified Components <partinfo>K398206 SpecifiedComponents</partinfo>

Designer: <partinfo>K398030 Designer</partinfo>

Status: <partinfo>K398030 Status</partinfo>

"

"