Team:UCL London/Fermenter Mechanics

From 2010.igem.org

(→Design of closure of the fermenter) |

(→Design of closure of the fermenter) |

||

| Line 193: | Line 193: | ||

Figure 6. Design of the closure of the fermenter (plan view). | Figure 6. Design of the closure of the fermenter (plan view). | ||

| - | [[Image: | + | [[Image:Bioreactor_Closure.png|500px|right]] |

Cs= 1/4 (3+√(Rc/Rk )) | Cs= 1/4 (3+√(Rc/Rk )) | ||

Revision as of 19:39, 27 October 2010

Fermenter Design

Utilitarianism, as defined by Jeremy Bentham (UCL) several assumptions that have to be made in order to solve an engineering problem, are acceptable. The first one was the model taken for the scale- up process. This was the original 1L fermenter used for the pilot scale of the E.coli cells.

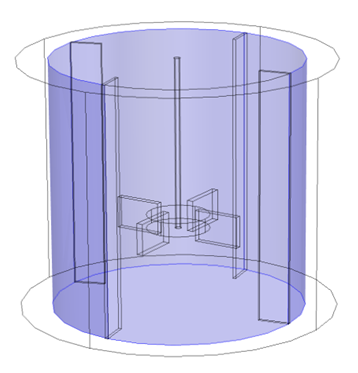

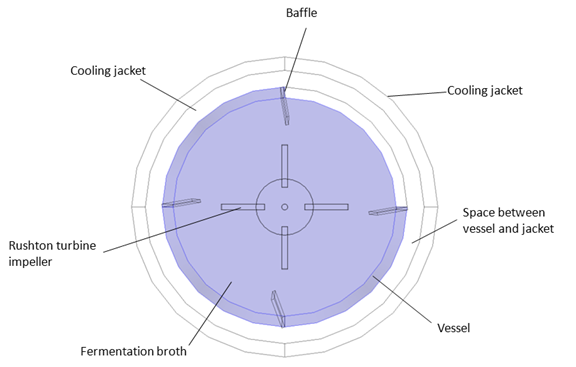

Assuming that a 1000L fermenter operating with 75% space efficiency (0.75) and 1 marine impeller (di=dv/2). The vessel aspect ratio is 2.5 that is Ah/d= 2.5 and the fermenter is aerated at 0.75 vvm (that is 0.75 volumes of air per volume of liquid per minute). The gassed power requirement per m3 is Pg/VL= 1860 W/m3 as it was found from the model used for the scale- up. Usually the industrial motors are used to deliver 1-3 W/L (Lye et Baganz, 2007). Therefore the 1.86 W/L was chosen on the assumption that due to engineering cell modifications, the E.coli cells are not so robust and thus extremely high power inputs should be avoided. Therefore the power input value must be kept to a minimum. A Rushton turbine four blade impeller is used as the axial flow type of impeller ensuring medium speed and ensuring medium growth rate but also good mixing.

What does fermenter design means?

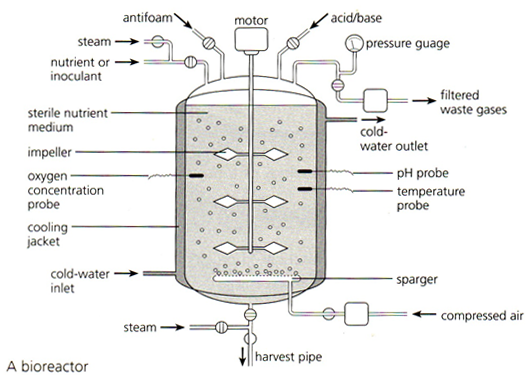

Well the importance of the design of the fermenter lies on the need to understand the broth's behaviour during its mixing. Again, we use the 'chocolate cake' as the analogy. We put the chocolate powder, based on a standard recipe (assumption) which in our case are the modified cells, the milk, which is the oxygen, the sugar, the butter and the eggs which are other crucial components for the success of our 'cake' like the nutrients. Second step we mixed them all in a cooking pot, which for the analogy used is the fermenter. Now, you would not use a plastic pot, as this would melt under high temperatures and you need to think of your ingredients, which opposed to cell broth, are not acidic or anything like that, but you still need to think of other factors that could cause leaching of the plastic, leading to the conclusion that you would not use a PVC one. So, you may use a ceramic one, again depending on what you cook; pasta would go in a stainless steel one, or a cake would go in a form with probably some oil spraying for the cake to be removed easily upon cooking. Similarly, the fermenter, or bioreactor as it is also known, should be Stainless steel. Moreover, when it comes to designing it, of course you use some standard values from literature, as with a standard recipe for example if you are cooking for 5 people the portion will differ significantly compared to a restaurant where the chefs cook for hundreds of people. Therefore, the cooking apparatus differ in size. Also, you need to critically think about your recipe itself; if you want to make changes, you can base it on your experience, on recommendations for experienced chefs as to on what ingredient goes with what. In a parallel way, designing the equipment, is based on experience, logic and some engineering calculations. Moreover, at some point, you may have to close the lid, so the fed batch mode where you could add other ingredients necessary during the "cooking process", is switched to batch by closing the system's input and letting the mixture get cooked. Also, you have to control the temperature, because obviously you do not want to burn your cake! That is why, there is a need for a careful design of a fermenter, with all the necessary probes, to control the pH, the temperature, to take out the first batch of "cooked cake" when is ready, to see through a sight glass, if the cells are growing- or the cake is getting ready- and control the fermentation process, like a real cook does with the food.

Mechanical Design of 1000L Fermenter

This report was conducted to estimate the dimensions and the materials needed for the construction of a 1000L fermenter for the production of Fab fragments (fragmented antigen binding) are the regions of an antibody expressed and secreted in E.coli cells. For the estimation of the dimensions of the fermenter empirical equations and rules of thumbs were exploited. The dimensions and the fermenter properties like the diameter, the height as well as the impellers speed, the baffles position and the driveshaft size were estimated on a scale- down model. The material used for the fabrication of the fermenter, the head end, the ports and the pipes is stainless steel to resist corrosion and maintain a clean and sterile vessel. The diameter of the vessel is 0.8m and the height is 2m.

The thickness of the wall is 6mm with a 0.15 m jacket surround it. The impeller’s speed is 3.3 m/s and the impeller used is Ruston Turbine four blades, suitable for the growth of E.coli cells. Therefore all the power requirements were satisfied ensuring the viability of the design. Five spray balls were found to be enough for a sufficient cleaning of the fermenter with their 360° coverage and placed on the inside of the torispherical head in a cross shape. Then the flowrate in the pipes was predicted enabling the calculation of the diameter. Basically all the information specified for every single part of the fermenter was taken from recommendations, advice from experts, theoretical predictions as well as engineering justifications. Last but not least emphasis is given on the importance of maintenance and annual shutdowns of the plant as well as regular checks to ensure its proper operation.

For the CFDs (computational fluid dynamics) COMSOL Multiphysics 4.0a was used. The modelling equations are the Navier-Stokes equations formulated in a rotating frame in the inner subdomain and in fixed coordinates in the outer one. No-slip boundary conditions apply at the bioreactor's fixed walls and the boundary condition on the rotating impeller were set to rotate with the same velocity as the no-slip counterclockwise rotation conditions.

Figure 1. The computational fluid dynamics of the bioreactor using COMSOL Multiphysics 4.0a. showing that the shear rate reaches its maximum value at the edges of the impeller and the baffle.

Navier-Stokes equations The governing equations for this model are the Navier-Stokes equations

(1)

combined with the equation of continuity,

(2)

where is the fluid velocity vector, the time, the pressure and the gravity vector.

For incompressible fluids at steady state hydrodynamics and isothermal conditions with negligible gravity, equations (1) and (2) become respectively:

(3)

and

(4)

Equations (3) and (4) are to be solved in the fluid domain in order to obtain the velocity distribution within the channels.

Comsol 3.5a®, specific modelling software for finite element analysis of partial differential equations, was used to solve equations (3) and (4).

Operation Cycle

The operation cycle for the fermenter involves start up, where process water is fed from the process water port and media is fed from the feed port into the vessel. The level of the liquid is measured using the level indicator probe. Once the required level is met then the ports close. Air is pumped through the air inlet to the sparger inside the fermenter.

There are three main modes of bioprocess operation: batch, fed-batch and continuous (Doran, 1999). The criticality of operating strategy is due to the significant impact is has upon the substrate conversion, product concentration, susceptibility to contamination and process reliability.

Initially, the reactor operation is fed- batch. That means that the mixed reactor starts operating by intermittent or continuous feeding of nutrients which is necessary for the broth. Therefore, additional fresh medium is allowed to enter the reactor with the flow rate and timing being monitored and controlled by the dissolved-ocygen level or exhaust gas composition. Then, after all the medium is in the reactor at the conditions set, we stop adding anything else in the reactor and the process takes place in a closed system.

Batch processes operate in closed systems where there is no more substrate addition but only removal of the end product (Doran, 1999). The most widely used reactor operation is batch with the classic reactor vessel being a stirred tank.

Figure 2. The CFD (Computational fluid dynamics) of the bioreactor. As the simulation shows, the regions where the broth is coming into direct contact with the baffles and the impeller have greater speed.

The temperature is brought and maintained to the optimum temperature. There are two probes in the fermenter which are at the greatest range i.e. opposite sides of the fermenter as shown in the drawing. This is to ensure the distribution of heat is even and the average of both sensors should read 37°C. The pH is maintained at a desired value by the addition of acid and alkali. Two probes for measuring the pH are placed inside the fermenter at opposite ends to ensure there is good mixing as this would be indicated if there was little change between the two probes.

Once the optimum conditions have been achieved the innocculum is fed through the innocculum port. Antifoam from the antifoam port is added to avoid foam formation which reduces the efficiency of the process. The exhaust gases are released from the fermenter whilst in operation and the pressure is maintained. The cells are grown for a certain period of time and the process is regulated using a series of automatic control loops.

Finally there is shut down, where the fermentation batch ends and in this step all the broth is collected into the harvest port.

After each operation cycle the fermenter will have to be cleaned and sterilized in place. CIP will be performed using acid and base detergents which will be pumped through the cleaning solution ports into the 3 spray balls. SIP requires that the fermenter and all pipes are sterilized with steam at 121°C. The steam will come from the acid, base and antifoam ports. Regular and annual maintenance checks will have to be performed to ensure everything is running correctly and as efficiently as possible.

Calculations of Bioreactor’s properties

Power Requirements Calculations

The operating pressure of the vessel was assumed to be 3.5 bar and the design pressure 3.85 bar. The operating temperature is 37°C but the design temperature is 4- 121°C allowing the introduction of steam to clean the vessel.

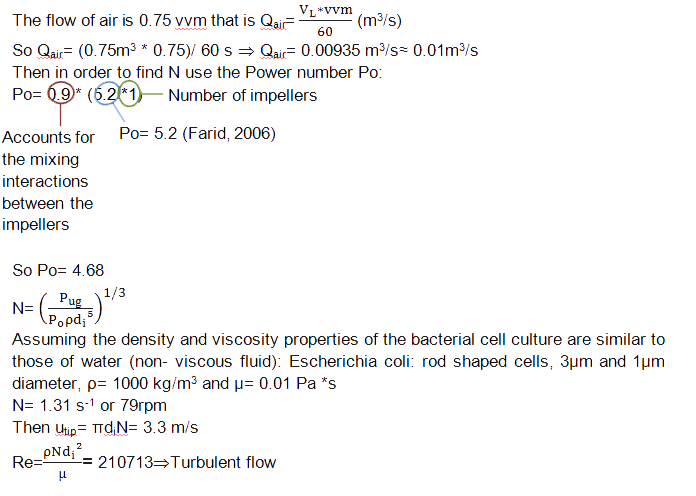

Figure 3. The geometry of the Rushton Turbine bioreactor, as constructed with COMSOL Multiphysics 4.0a. Starting by assuming Pg=0.4

Pg= (Pg/VL)* VL

With Pg usually between 1-3 W/L, so Pg/ VL= 1860 W/m3 (small scale) and need to find the properties of the 1000L fermenter:

VV= 1000L= 1m3

VL= 0.75* 1m3= 0.75m3

Q_air=Vair/t=(VL*vvm m^3)/(60 s)

The fermenter is aerated at 0.75vvm, i.e. 0.75 volumes of air per volume of liquid per min

Then Pg= 1860 W/m3 * 0.75m3 which is the total gassed power input for the 1000L fermenter => Pg= 1395W

Then Pug= Pg/0.40“rule of thumb” which is 1395W/0.4= 3488W

The aspect ratio of the vessel height to the vessel diameter could be from 1-3 and according to experts (Jacobs) for mammalian cells the value of 2 is advicable.

A_h/d= 2.5 => hv/dv =2.5 Then used: dv=((4Vv)/(A_(h/d) π))^(1/3) => dv=((4*1 m^3)/(3*π))^(1/3)=0.7515 m≈0.8 m

So hv= 2.5* 0.8m= 2m The minimum thickness required can be calculated from the equation With f= 135N/mm2 for 150°C (121°C actually)

Pi= 3.5 bar= 3.5* 105 Pa, Di= 0.8m and f= 135*106 N/m2 Then => e= 1.03*10-3 m ≈ 0.001 m or 1mm

The minimum practical wall thickness of the vessel though should be 2mm. The vessel diameter’s is 0.8m and for vessels of 1m diameter the minimum thickness should be 5mm (Sinnott, 2000).

Jacket

The space between the jacket and the vessel is estimated based on the size of the jacket. According to Sinnott (2000) the size of the jacket is 50mm for small vessels and 300 mm for large vessels. The assumption made is that the jacket’s size should be: 150 mm for the 1000L fermenter.

The jacket surrounding the fermenter will be made out of stainless steel 304 and its thickness is the same as the fermenter. The wall thickness of the fermenter was estimated to be 6mm based on rules of thumb including an additional 2mm allowance for corrosion.

Impeller Size & Speed Calculation and Reynolds Number Estimation

Then the diameter of axial mixers was based on the empirical statement (Lye, 2006) that is over 0.33 to 0.5 the tank diameter. So assumed to be 0.45 timed the diameter of the vessel, that is dm= 0.45* 0.8m= 0.36 m and the spacing is usually 1-2 impeller diameters of 1 tank diameter (Lye, 2006).

So spacing, based on 1.5*dT=0.36*0.8m = 0.3m impeller spacing of one impeller from the other.

Driveshaft & Blades Size calculation

Then the impeller driveshaft was decided to be bottom driven as this is recommended in small industrial scale production where the shaft is shorter, gives better power development leaving more space on top plate for ancillaries with only one drawback of a more difficult seal arrangement (Lye et Baganz, 2007).

Figure 4. The velocity field of the bioreactor.

The shaft diameter was calculated by the inequality below:

ds > or = [((100*L*Pug ))/((π^2*Νdi*f) )]^(1/3)

The shaft length was assumed to be 1.65 m (slightly above the liquid’s level).

f is the design stress which is taken from literature which is 175 N/mm2 for stainless steel 316L working at 37°C. The shaft diameter found is 0.07 m.

Then the blade thickness: dbt > or = [((9P_ug ))/((32πnNf) )]^(1/2)

where n is the number of impellers, so n=1

dbt=0.002 m

Blade width= 0.2* di= 0.16m

Blade height= 0.25* di= 0.20m

Disc diameter= 0.75* di= 0.60m

Disc thickness= Blade thickness= 0.02m

Baffles & Orifice Sparger

It was decided that four diametrically opposed baffles would be put in the vessel. The size of each baffle should be 0.1- 0.05 tank diameter. The assumption made here is that the baffle’s diameter= 0.1*dT= 0.1 *0.8m= 0.08m or 8cm. The baffle height is dependent on the gas holding or it accepted to be equivalent to the cylindrical height of the vessel. In this case it was assumed to be slightly above the liquid’s level. Small gap between vessel and baffle is recommended to stop biomass build up, enhance oxygen transfer and cleaning solution (Lye et Baganz, 2007). The gap is 0.1 of the baffle width fixed to the vessel such that they can be removed. Also it is recommended that baffles are placed at an angle as with were found from experts to enhance scouring (Lye et Baganz, 2007). The dimensions of the baffles were estimated based on empirical equations relating their size to the vessel’s size.

Figure 5. The cross sectional view of the 1000L bioreactor.

Therefore in the mechanical drawing the baffles were drawn at an angle of 10° to the vertical pointing anti- clockwise since the flow direction is clockwise. That was decided after some thought and with the preparation of a computational fluid dynamic model to predict the flow of the fluid. Also the base of the cylindrical vessel was chosen to be rounded at the edges since in this way it discourages the formation of stagnant regions.

An orifice sparger was placed under the bottom impeller and its size was calculated to be 75% the impellers diameter that is 3.375 cm (4 cm for easier design). The holed on this circular ring must not exceed 6 mm and therefore for design calculations their size was assumed to be 5 mm. A magnetic drive was chosen as the driveshaft seal as this is more common in non- viscous fermentation broths like Escherichia cell culture which is a very dilute culture since the cell density is low.

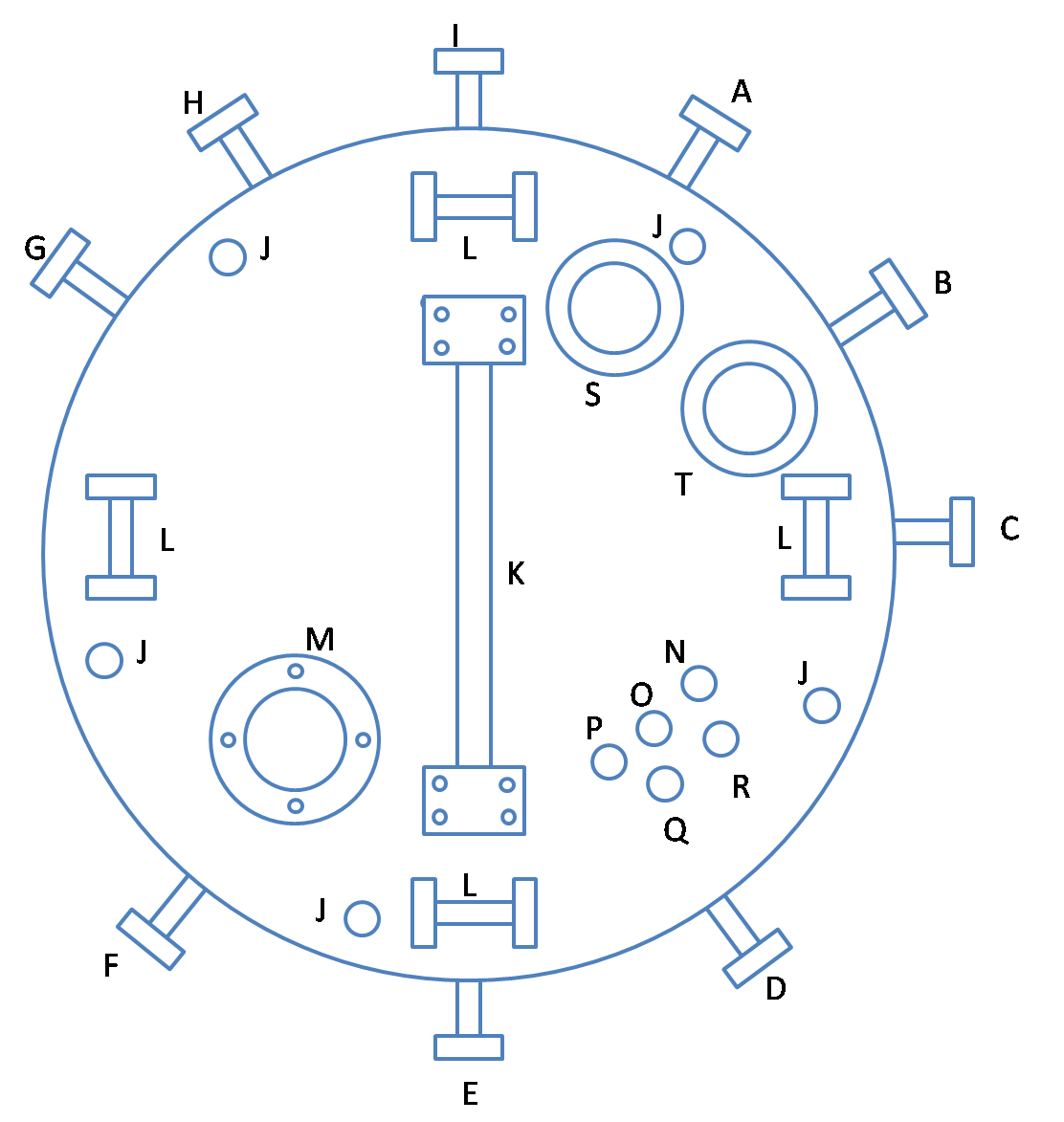

Design of closure of the fermenter

It was decided to use a standard torispherical head since it is widely used in industry and can withstand operating pressure up to 15 bar. The bending and shear stresses were taken into consideration in the design of the heads. For the estimation of these stresses usually caused by dilations of the vessel a basic equation used for a hemisphere was used. The knuckle and crown radii were found from empirical values allowing the stress concentration value determination that allowed with its turn the estimation of the thickness of the head.

Figure 6. Design of the closure of the fermenter (plan view).

Cs= 1/4 (3+√(Rc/Rk ))

where Cs is the stress concentration factor taken to allow for the increased stress due to the discontinuity. Rc= crown radius (not to be more than the vessel’s diameter) Rk= knuckle radius The ratio Rc/ Rk should not be less than 6% (to avoid buckling).

e= (Pi*Rc*Cs)/(2fJ+Pi*(Cs-0.2)) For formed heads (no joints in the head) J=1.0

Pi is the internal pressure and f is the design stress (literature value). The design pressure= 110% of the operating pressure (Coulson and Richardson, 2000)

In this case, the fermenter is operating at 3.5 bar therefore the design temperature is 3.85 bar. Operating temperature= 37°C mammalian cell culture, cleaning solution 4°C for the cooling water and 121°C for the steam (CIP)

f= 135 N/mm2 (stainless steel corresponding to operating temperature 150°C) Rc= 1.5 m hence Rk= 0.06*Rc So Rk=0.09 m So e= 7 mm (5mm+ 2mm for corrosion allowance)

For design purposes it was assumed that the wall thickness and the end thickness are the same, 6mm. Basically, the wall thickness has an impact on the overall heat transfer coefficient while the end thickness affects the mixing characteristics of liquid inside and since the vessel is metal, the value of the thickness means it would aid cleaning.

Calculation of the dead weight of the fermenter

For preliminary calculations, the approximate weight of a cylindrical vessel with domed ends and uniform wall thickness can be estimated with the following equation:

Wv=Cv*(π*ρm*Dm*g(Hv+0.8Dm)*t Where Wv is the weight of vessel

Cv is a factor for the weight of nozzles etc= 1.08

Dm= Di+t where Di is the internal mean diameter of the vessel

For steel vessels the above formula becomes:

Wv=240*Cv*Dm*(Hv+0.8Dm)*t

All the ancillary equipment attached to a tall vessel will subject the vessel to a bending moment if the centre of gravity of the equipment does not coincide with the centre line of the vessel according to Coulson and Richardson. The moment produced by small fittings e.g. ladders, pipes and manway will be small and hence can be neglected. For this mechanical drawing though the moment equation is only being mentioned. Me=We*Lo where Me is the moment, We is the dead weight of the equipment and Lo is the distance between the centre of gravity of the equipment and the column centre line. From calculations, Wv= 3.2194 m3 say 3.3 m3 (3300 L or 3300 kg).

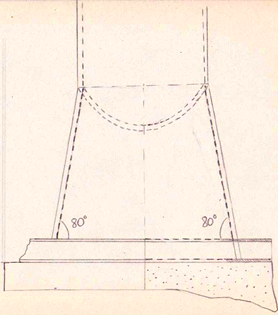

Fermentation Support with skirt

The choice of skirt support was based on that skirt supports are used for tall, vertical columns to carry the weight of the vessel and contents. Therefore the vessel support should be designed not to impose any localized loads on the vessel wall and to allow easy access to the vessel and fittings for inspection and maintenance. A flange at the bottom of the skirt transmits the load to the foundations. Last but not least, the skirt that the fermenter will be placed in was chosen to be a conical one with the angles of the base to be 80° as it is predicted to equally distribute the weight of the fermenter and ensure no collapse and balance of the whole equipment system. The minimum thickness should not be less than 5mm. Assume to be 9mm.

The stresses in the skirt can be found by calculating other outside parameters that influence the vessel’s stability besides the dead weight of the vessel or the size of the vessel with its contents like the wind loading and the earthquake acceleration. These can be found by measuring the wind speed, the density of air and hence calculating the pressure of the wind on the vessel which in turn can be used to find the stress acting directly to the fermenter. For the purpose of this study though these parameters where neglected.

Figure 7. The skirt of the fermenter, hand drawn.

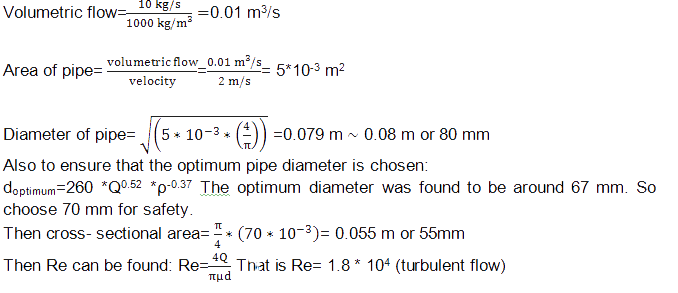

Pipe dimensions

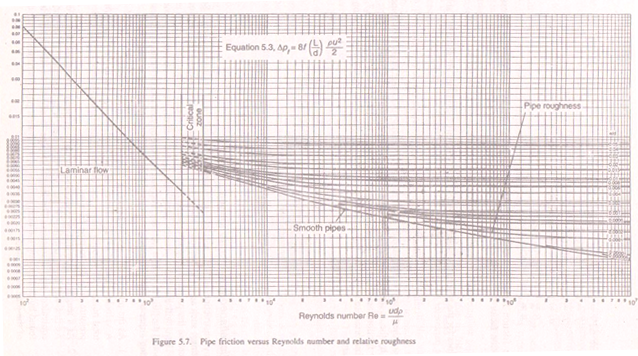

The diameter of the pipes connected to the fermenter for the air supply, air exhaust, inocculum introduction and media feed as well as the ports for the introduction of acid, alkali and anti- foam when necessary were calculated based on predicted flowrate and on the Reynolds Number representing the type of flow needed for each case. Due to the not so high operating pressure the process pipes are thin cylinders with a thickness of 2.5 mm. For the determination of the pipe dimensions turbulent flow is assumed with the Reynolds number to be > 104 to enhance good mixing of each fluid with the broth.

As a rule of thumb, liquid velocities are usually in the range 1-3 m/s in order to minimize the presence of stagnant unmixed pockets of fluids but also to extend the lifetime of the systems (Farid, 2006). Therefore assume v= 2 m/s. The mass flow, based on values (Farid, 2006) used in industry was assumed to be 10 kg/s.

Pressure drop calculation (in the pipe):

Friction loss per unit length, f: Re=(ρ*v*dp)/μ= 9000 ( > 104 therefore turbulent flow)

Then the absolute roughness for commercial stainless steel pipe e= 0.046mm is found from tables (Coulson and Richardson, 2000) and hence the relative roughness can be calculated.

e/d= 0.046mm/70mm=6.58*(10^-4)

Use Moody chart to find the Fanning Friction factor: f= 0.0025

Figure 8. Moody Chart (Sinott, 2000)

Then the wall thickness can be found by: t=(P*d)/(20*σd+P)

The working pressure is 3.5 bar and the design stress at the operating temperature of 121°C which is the maximum working temperature (150°C from the table for stainless steel 316L) is 135 N/mm2 and 1 bar= 105 Pa. t=10-3 mm Basically the process pipes can be considered as thin cylinders. Also allow 2mm for corrosion. That is 2.5mm as a standard pipe diameter.

Sprayball

For the 1000L fermenter it was decided that 3 spray balls of 75mm size each are suitable for a satisfactory cleaning. The height of the ball with the connector is 90 mm and the shape of the ball is the standard round shape provided by Toftejorg. The sprayball has thick wall, 4mm, offering more efficient cleaning and is made out of 316L stainless steel to avoid corrosion caused by the cleaning solution. There will be holes at the top, at the sides and at the bottom of the ball to ensure a 360° cover of the fermenter.

Figure 9. A typical bioreactor – adopted by Industrial Ferments: growing cells on a large scale by Keith Hicks (2009).

Sight glass

The placement sight glass placed on the fermenter is a way to look into the actual process when it takes place. Usually a 15 cm window is placed, so for design purposes a 16.5 cm window was chosen. Also the height at which the sight glass was put was empirically predicted to be 15 cm outside the vessel for a wider view. The glass will be surrounded by a stainless steel 304 collar which less expensive compare to the 316 L since there is no need for it, with a diameter of 30 cm. That is 13.5 cm layer around the glass. Also a switch for LED light is assumed to be needed to the sight glass for better viewing. For the sight glass, borosilicate is used due to its physical strength, making it resistant to thermal shock and chemical attack (Sinott, 1999).

Ports

There are several ports needed to be installed in the fermenter like probes, acid, base and anti- foam inlets which correct the pH when required, as well as outlet ports for drainage and their size have to be estimated before the construction of the fermenter. Usually a 25 mm port is used for probes and sampling while the 34 mm is for some additional ports. The decision made here was that a 34 mm port would be the ideal size for all the ports with no exceptions and depending on the demand the flowrate of each component coming in or out of the fermenter will be adjusted accordingly.

Choice of materials

From a detailed research of currently available fermenters in industry for the production of biopharmaceuticals, the bioreactor will be made out of stainless steel 316L (low carbon) since the use of clean steam causes corrosion to the vessel and therefore it is extremely important to use clean steam for the mammalian cell culture. (Lydersen et al, 1994). Also the choice of SS316L is suitable for technical purposes like welding characteristics. The quality of vessel welds is to ensure the maximum possible smoothness and cleanibility as well as to minimize corrosion. According to Lydersen et al (1994), the welding of an aseptic fermenter should be done under inert gas shielding to minimize oxidation and flux residue and to yield smoother welds. Therefore the use of a 316L and not the 316 stainless steel reduced carbide precipitation and consequent pitting near the welds.

For the head end silicone will be used at the flange point and the for the other static O- ring seals EPDM (ethylene propylene diene monomer) as this is recommended from the Bioprocess Engineering book for system, equipment and facilities on the fermentor design section by Lydersen at al.

Jacket, Surface treatment & Polishing

The space between the jacket and the vessel is estimated based on the size of the jacket. According to Sinnott (2000) the size of the jacket is 50mm for small vessels and 300 mm for large vessels. The assumption made is that the jacket’s size should be: 150 mm for the 1000L fermenter.

The jacket surrounding the fermenter will be made out of stainless steel 304 and its thickness is the same as the fermenter. The wall thickness of the fermenter was estimated to be 6mm based on rules of thumb including an additional 2mm allowance for corrosion.

The stainless steel fermenter is important to be cleaned and treated in a way so as corrosion will be prevented during operation conditions. So there is an inside and outside surface finish that permits the easy and hygienic cleaning of the vessel. On the stainless steel surface there is a microscopically thin, invisibly chromium oxide layer that prevents corrosion of the vessel when the vessel is clean and polished. The surface finish is more for aesthetic purpose rather than for functional reasons.

A mechanical surface treatment is used for the steel vessel. The smoothness and quality of the mechanically treated surfaces are defined by Ra, Rt or RMS values which account for the roughness of the surface and usually in biotechnology surface qualities of Ra around 0.6 µm (220 grit) is the minimum requirement. According to Lydersen et al, the steel grade 1.4406 (AISI 316 L) gives the best possible smoothness value. Therefore a minimum finish of 0.51- 0.64 µm is common and it for the 5500L of this project it was decided to go for a 240 grit, that is 0.38-0.51 µm. This polish number presented by the ‘grit’ term number is defined as the number of silicon carbide particles per square inch of abrasive pad or as the number of scratches per linear inch and a higher grit number means a smoother finish (Lydersen at al, 1994).

In addition to the mechanical polishing an electropolishing step removes metal from the surface by anodic dissolution in a suitable electrolyte with an applied current. The advantage of this treatment is that it is smoothes roughness in the surface area which cannot be seen with naked eye.

Inspection and Maintenance

Access to the inside of the fermenter is required for the supervision of the impellers, the baffles, the driveshaft, to ensure that the magnetic coupling seal works properly and that the orifice sparger works without interruptions that would lead to product damage. For this reason a removable domed end (torishperical head) was chosen. In addition to that it was thought that the addition of metallic lifting lugs would make the dismantling removal easier with the use of crane equipment.

Six different probes for temperature, DOT, pressure, pH and oxygen and carbon dioxide level indication each one along with 2 back up indicators each in case of failure were put to the fermenter as well as a viewing sight glass while the inlet and outlet ports are used for the addition or removal of the necessary materials to ensure the proper operability of the fermenter. Moreover to ensure that sterility is maintained the use of O rings is assumed. It was decided that the O rings will be made of EP (ethylenepolypropylene rubber) since it is the most widely used and validated material in biotechnology and food technology and the EP seals range from -40 to 160° C, are resistant to water, steam and aging.

For the stainless steel tubing sanitary clamp seals with flat gasket are used in the U.S.A. fixed with a Tri- clamp® (Lydersen et al, 1994). Regular checks on the pipes, valves, flanges points, probes, sparger, control loops, impeller, jacket, weld points is crucial to maintain the fermenter in a good condition for better efficiency, less money spent on replacing broken parts and extending its lifetime (although it is expected to work for about 10 years). In addition to that, an annual shutdown is required to check for degradation, deformation of pipes, fatigue of materials, cracks and nicks inside or outside the fermenter.

Typically, 3-5% of fermentations in an industrial plant are lost due to failure of sterilisation procedures. However in antibiotic fermentations like in this project, fewer than 2% of production scale antibiotic fermentations are lost through contamination by microorganisms or phage (Doran, 1999).

Industrial fermenters are designed for in situ steam sterilisation under pressure. For effective sterilisation, all air in the vessel and pipe connections must be displaced by steam. After sterilisation, all nutrient medium and air entering the fermenter must be sterile.

Maintenance is required to ensure the fermentation process is achieving its goals, to identify any problems that may occur and ultimately keep the process working as efficiently as possible to save on costs. Maintaining the fermenter can significantly reduce the overall operating cost as well as minimise the risk of any hazards. For maintenance, the top of the fermenter can be removed to allow access of maintenance personnel for any repairs that may be required. For large vessels a domed construction at the top to allow access to personnel is less expensive and so this has been chosen in the design (Doran, 1999).

Once the design has been built and approved by British Standards 5500, the fermenter can then start to operate (Sinott, 1999). Maintenance is crucial and the fermenter must be monitored at all times. Most measurements can be made on-line through probes in the vessel which are sensors that detect changes in many variables such as temperature and pH. However, whilst monitoring some values there may always be a delay. For example, in a typical fermentation, the time scale for change in pH and dissolved-oxygen tension is several minutes to make sure they are all correctly calibrated and functioning properly and as efficiently as possible. This is to avoid any problems that may be caused because of a false reading. For example if the pH probe is not working properly and the pH is either too high or too low, then the cells would die and also the product may denature. Also possible blockages in pipes or broken valves must be checked regularly. Oxygen supply through bottom sparging should also be checked regularly, as cells die without it and that would mean a significant loss in time and money if the fermenter has been running for several days.

Figure 10. The basic construction of the bioreactor, using COMSOL Multiphysics 4.0a., shows the baffles, the impeller, the jacket and the vessel wall clear geometry without any broth.

The fermenter requires annual shutdown to check for possible corrosion on the internal surface and also on the impellers. Corrosion may reduce the speed and efficiency of them impellers and the shaft too. This needs to be maintained at a high standard to ensure good mixing in the fermenter for growth of cells and product. Baffles also need to be checked for to see the level of corrosion. Also there may be possible fouling in the jackets and general piping problems, such as blockages and leakages, as well as overall contamination in the system. As previously mentioned in the design a 2mm allowance for corrosion had been added on the thickness of all equipment. The annual check would see how much all the equipment has been eroded and identify any problems to resolve them.

The aim of the Mechanical Drawing is to provide a detailed analysis of the construction and operation of the fermenter that is a technical way of presenting this piece of equipment. In this section the dimensions and materials of construction of a 1L fermenter were estimated. The fermenter is used for the growth of Escherichia coli cell culture for the production of therapeutic fragmented antibodies.

Conclusion

The importance of carrying out a carefully designed fermenter lies to the fact that product safety (US term according to Jacobs) is the number one demand. Therefore the quality of the biopharmaceutical product is the factor that drives all the operational requirements of the process. Starting from the knowledge of the culture itself defines the specifications required to design a safe and operable piece of equipment. Therefore it is essential to specify all the parameters driving this process from the impeller power to the temperature indicator, from a small detail such as the angle of the baffles until the end closure of the vessel, as well the materials for the vessel’s fabrication found to be most suitable from previous work and industrial operations. Sometimes in order to define the dimensions of the fermenter or parts of the system, a rational analysis or a sound engineering judgment is needed over mathematical equations.

It is believed that the purpose of this section was not to lead the future engineer how to look for literature values on the ‘bible of design’ but to develop the critical thinking. Last but not least regular inspections and maintenance is essential to ensure a safe operation of the fermentation step. The cells are grown in a very carefully controlled environment; by adjusting the pH, the acid as needed is aided to regulate the growth of the cells. Moreover, all pipework connected to the fermenter is sterilised prior to fermentation. The aerobic fermentation process is driven by the motor and the driveshaft with the impellers on it, which they continuously stirr the cell broth. Moreover, the jacket is required to cool down the fermenter since the rise in temperature of the culture rises by more than 1°C per hour but a sharp rise in temperature could kill the microbes if not cool.

"

"

Twitter

Twitter Facebook

Facebook UCL

UCL Flickr

Flickr YouTube

YouTube