Team:Groningen/Project

From 2010.igem.org

(→Self assembling hydrophobic biofilm) |

|||

| (35 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

| - | |||

<html> | <html> | ||

| + | </html> | ||

| - | + | == Self assembling hydrophobic biofilm == | |

| - | + | [[Image:chaplin cell.jpg|right]] | |

| - | + | Surface hydrophobicity is a very useful property and is used in many applications ranging from raincoats, antifouling coatings, anti-bacterial and anti-fungal coatings and applications in the field of biomedical sciences to protection of highly sensitive sensor equipment. Hydrophobicity keeps a surface water free and thereby clean and dry, this prevents micro-organisms from fouling surfaces and corrosion from forming. Most hydrophobic coatings used today are either costly or contain harmful chemicals. So why not create an organism that does the work for you. | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | The idea is to engineer a bacterium that once applied on a surface, starts forming a [https://2010.igem.org/Team:Groningen#/biofilmfast rigid biofilm]. Completion of the biofilm will trigger the [https://2010.igem.org/Team:Groningen#/expression expression] of [https://2010.igem.org/Team:Groningen#/hydrophobins hydrophobic proteins] by the biofilm forming bacterium. These hydrophobic proteins will be incorporated in the rigid biofilm, causing strong hydrophobic surface activity. After the hydrophobic biofilm production, a [https://2010.igem.org/Team:Groningen#/killswitch_model kill switch] would be activated to kill of all bacteria. The result of these processes will be a surface that is coated by a rigid biofilm with embedded hydrophobic proteins, leaving the coated surface extremely hydrophobic. | |

| - | + | ||

| - | + | Producing a hydrophobic biocoating that is self assembling, would have a lot of advantages. | |

| - | + | Firstly it is relatively cheap to apply bacteria to surfaces. And since the coating process will be done by the bacteria themselves, there is no high-tech treatment involved and there are no expensive chemicals necessary to attain the hydrophobicity. | |

| - | + | Secondly, because these hydrophobins are proteins, they are in contrast to many chemical hydrophobins non-toxic to the environment. Applications of this hydrophobic biofilm could range from antifouling coatings on ships, antifungal coatings and corrosion and water protecting coatings. | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

Latest revision as of 21:55, 27 October 2010

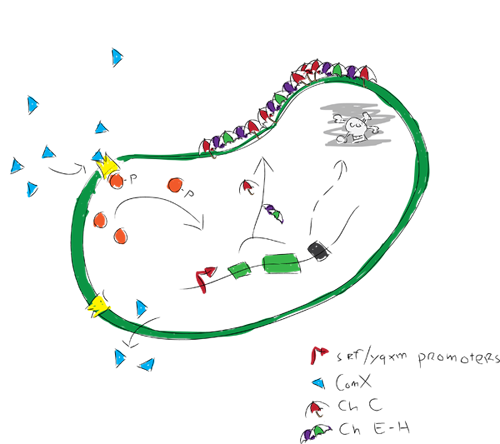

Self assembling hydrophobic biofilm

Surface hydrophobicity is a very useful property and is used in many applications ranging from raincoats, antifouling coatings, anti-bacterial and anti-fungal coatings and applications in the field of biomedical sciences to protection of highly sensitive sensor equipment. Hydrophobicity keeps a surface water free and thereby clean and dry, this prevents micro-organisms from fouling surfaces and corrosion from forming. Most hydrophobic coatings used today are either costly or contain harmful chemicals. So why not create an organism that does the work for you.

The idea is to engineer a bacterium that once applied on a surface, starts forming a rigid biofilm. Completion of the biofilm will trigger the expression of hydrophobic proteins by the biofilm forming bacterium. These hydrophobic proteins will be incorporated in the rigid biofilm, causing strong hydrophobic surface activity. After the hydrophobic biofilm production, a kill switch would be activated to kill of all bacteria. The result of these processes will be a surface that is coated by a rigid biofilm with embedded hydrophobic proteins, leaving the coated surface extremely hydrophobic.

Producing a hydrophobic biocoating that is self assembling, would have a lot of advantages. Firstly it is relatively cheap to apply bacteria to surfaces. And since the coating process will be done by the bacteria themselves, there is no high-tech treatment involved and there are no expensive chemicals necessary to attain the hydrophobicity. Secondly, because these hydrophobins are proteins, they are in contrast to many chemical hydrophobins non-toxic to the environment. Applications of this hydrophobic biofilm could range from antifouling coatings on ships, antifungal coatings and corrosion and water protecting coatings.

"

"