Team:Johns Hopkins/Notebook

From 2010.igem.org

(→Microfluidics) |

Arjunkhakhar (Talk | contribs) (→Microfluidics) |

||

| Line 63: | Line 63: | ||

<br> | <br> | ||

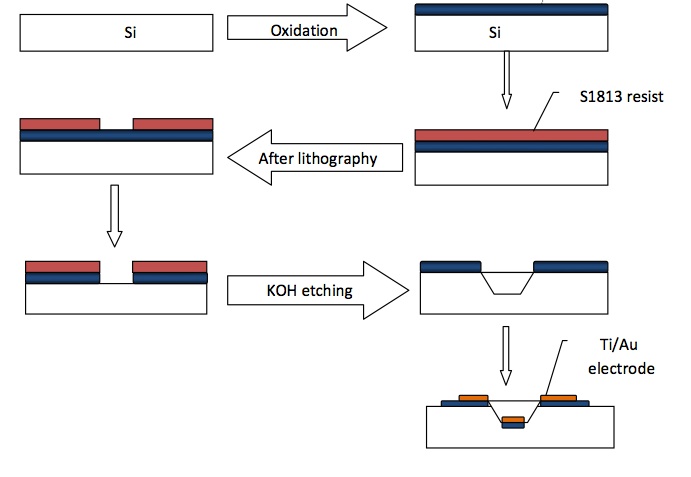

The process: | The process: | ||

| + | <br> | ||

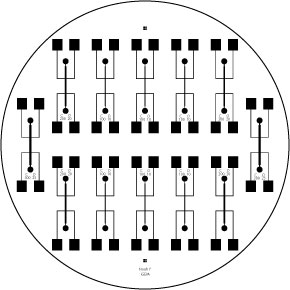

[[Image:Lithography.jpg]] | [[Image:Lithography.jpg]] | ||

<br> | <br> | ||

Revision as of 02:58, 27 October 2010

Device Design

Microfluidics

Protocol for creating silicon channels with metal electrodes

1. We grow an oxide mask. The Si wafers are put into an oxidation furnace to grow a layer of SiO2 that’s about 200 nm thick so that it can be used as a mask for the etching of Si in KOH. Water vapor is used to oxidize the Si and the oxidation temperature is 1100 C.

2. We then use photolithography to pattern the channels into the silicone wafer. We use a mask and positive resist S1813, coating with a spin at 3500 rpm for a minute to get about 1.2 um layer. Then we bake the wafer at 95C for 2 minutes. The wafer is then exposed to 100mj/cm/cm of UV radiation and then developed in developer CD26 for about a minute. This is followed by a DI water rinse then it is dried.

3. We then etch the oxide mask using buffered HF or BOE solutions, in which the etching rate is about 80nm/min.

4. The resist is then removed by spraying acetone onto the resist followed by IPA to wash away acetone.

5. The fluidic channels are then etched into the Silicone wafer using heated KOH, in which the etching time depends on the desired depth of the channels. The etching rate is about 0.5 micron per minute at 70C. We had etching times of 40 minutes for 20 micron deep channels.

6. The remaining oxide is then removed in BOE solution.

7. We then grow another layer of oxide on the wafer to electrically isolate the metal electrodes and the substrate.

8. We then apply the same photolithography technique described in step 2 to define the electrodes on the wafer. We use mask and a thicker layer of photo resist this time because of the topology of the wafer.

9. We then deposit Au on the silicone wafer using an electron beam evaporator. This results in a uniform 100 nm thick layer of Au on the wafer.

10. We then remove the resist in acetone then IPA.

11. Finally we use photolithography to remove the unwanted oxide, using a third mask.

12. A glass slide is then drilled using special ultrahard drill bits, such that the holes are aligned with the inlet and outlet of the microfluidic chip.

13. These glass slides are the bonded to the silicone wafer and the device is ready for use.

The process:

Overlay of our electrode and channel masks:

Experiments

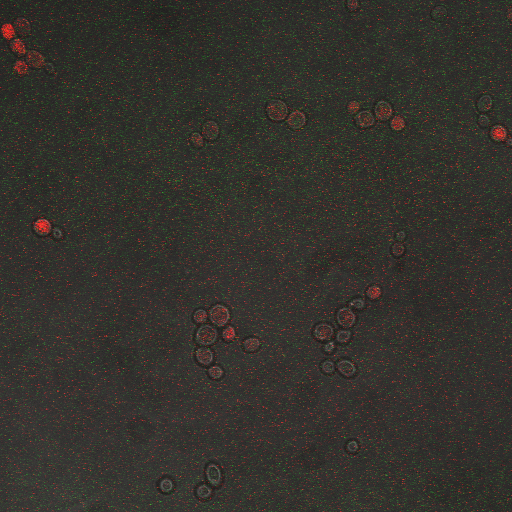

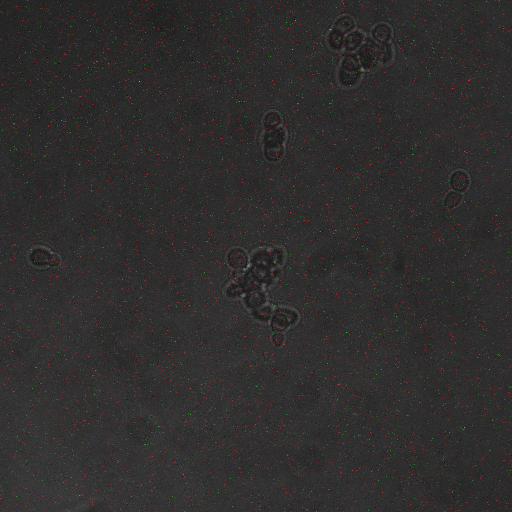

Crz1-GFP Experiment

Reason for doing the experiment: To establish whether shocking the cells induces calcium influx leading to CRZ1 nuclear localization.

Date: 21/7/10

Location: Imaging Center

Name of S. cerevisiae strain: Delta VCX1 Delta PMC1 with Crz1 tagged with GFP

Representative images:

Conclusions and discussion:

From this experiment it is clear that there is a calcium influx into the cell on application of a voltage across the cell membrane. We have also established that there is a significant influx of Crz1 into the nucleus associated with this calcium influx as we expected. We hypothesis that the reason we saw Crz1 nuclear localisation only in cells very close to the live electrode because the voltage provided by the function generator was too low to reach across the gap, and so a hypothetical ground gets formed near the live electrode. Another reason may be that as our device has the electrodes at a large distance from each other, comparable x.

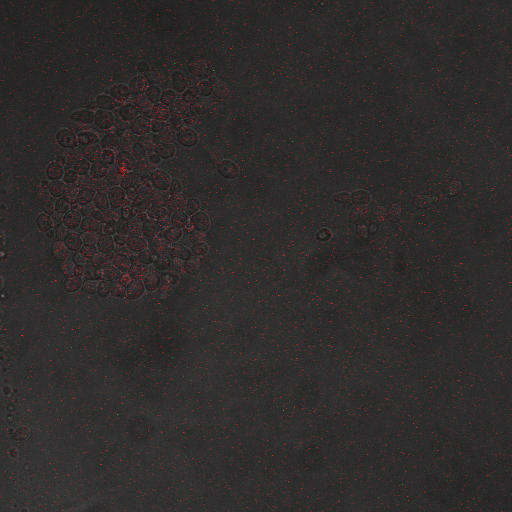

CDRE Optimization Experiment

Reason for doing the experiment:To find an optimum voltage amplitude and shocking time for yeast containing the CDRE-RFP plasmid.

Date:10/7/10

Location: Imaging Center

Name of S. cerevisiae strain:Delta VCX1 Delta PMC1 W303 with CDRE-RFP

Representative Images:

Results

| 2s | 5s | 10s | 20s | 40s | 80s | |

|---|---|---|---|---|---|---|

| 10V | None | None | None | None | None | N/A |

| 8V | None | None | None | None | High | High |

| 6V | None | None | None | None | Moderate | High |

| 4V | None | None | None | None | Low | Low |

Conclusions and Discussion:

First, observe that the channels are inactive for the lowest stimulus durations. Some of these durations are on cellular diffusive timescales, so not enough calcium can enter the cells. Also, cells can quickly move to extrude the excess calcium.

Second, consider the channel mechanics. Calcium channel gates alternate between open and closed states based on first order kinetics, where the rate constants are exponential functions of voltage. The open probability curve increases rather steeply, made even steeper since having n channels raises the probability curve to the nth power. This curve was found to rise rapidly between 4V and 8V to a maximum around 8V. At 10V, however, shorter stimulus durations are insufficient to trigger calcineurin, but longer durations kill the cells.

From our experiments we found that there was significant expression of RFP after 40 seconds of shocking. We can also establish that a ten volt voltage amplitude kills most of the cells, which from literature (REFERENCE) is probably due to membrane disruption. The maximum expression we can get without damaging the cells is with an 8V shocking voltage amplitude.

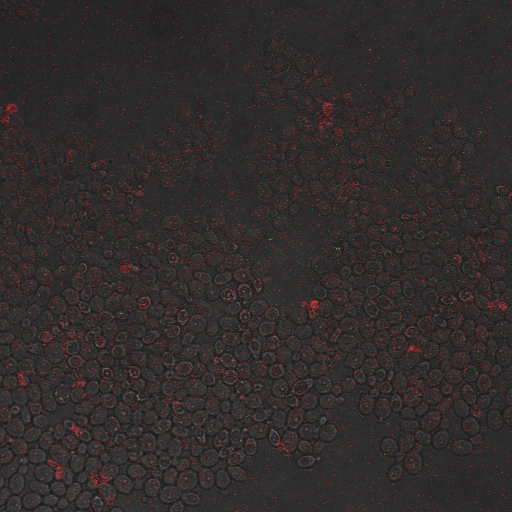

CDRE hone in Experiment

Reason for doing the experiment:To hone in on the CDRE systems region of activation with respect to time of shocking. Also to compare yeast without PMC1 and VCX1 knocked out versus yeast with it knocked out to determine effect of the knockout on the CDRE systems expression levels.

Date:10/7/10

Location:Imaging Center

Name of S. cerevisiae strain:Delta VCX1 Delta PMC1 W 303 with CDRE-RFP

Observations:

From the imaging of the shocked knock out yeast cells we find that the cells start expressing RFP after 90 seconds of shocking. We saw expression in all the samples between 90 and 130 seconds with a definite trend of increase. The overall expression of RFP was pretty low, however, and only a few of the total cells expressed. It was also difficult to establish cytosol localization of RFP due to clumping of cells. We saw no expression of RFP in the 0 second shock trial.

From imaging the non knock out yeast samples we found very high expression levels overall. There was constitutive expression in the negative control i.e. the 0 second shock trial, and the expression of RFP increased rapidly with increased shocking time, with maximum saturation at 50 seconds. After this its was not possible to visually distinguish weather there was any increase in expression levels. There was definite localization of RFP in the cytoplasm. In the non-knocked out samples, most of the cells expressed RFP. Another observation made during imaging was that the non-knock out cells were a lot healthier looking and bigger than the knock out cells.

Results

Conclusions

From this experiment we can conclude that the CDRE –RFP plasmid was successfully inserted into the PMC1, VCX1 knockout yeast strain. We can also establish that the activation of region of the CDRE –RFP system is between 90 and 130 seconds of shocking, with a definite increase in expression levels with an increase in time shocked. We can also establish that there is no constitutive expression of CDRE – RFP from the fact that there is no RFP seen in the 0 second control. The overall expression of the system is weak however and it is only after 110 seconds that more than half of the cells in the frame start to express. We also observed that the knock out cells are smaller and less healthy looking than the non knock out cells, which is probably because they are less able to deal with calcium shock induced by shocking and so more strained and unhealthy.

From the images of the non knocked out yeast we can see that there is significantly higher expression levels with constitutive expression. We also can see that the rate of increase in expression with time is much higher and the region where the CDRE gets activated is much earlier than with knocked out yeast. We theorize that the reason for this increased expression in non knocked out yeast could be because of a combination of two reasons. First, because they do not have PMC1 and VCX1 knocked they have the ability to pump calcium out of the cytosol and into vacuoles making them more resistant to calcium shock and hence more healthy and better able to express the RFP. The other possible reason is that PMC1 and/or VCX1 may have feedback loops, and as PMC1 does have constitutive expression the non knockout cells may be having their RFP expression rates amplified by this effect. We believe that a combination of these two effects causes the increased expression rates.

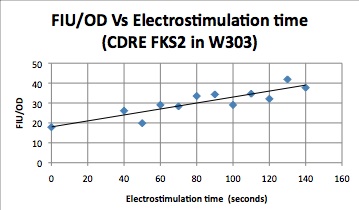

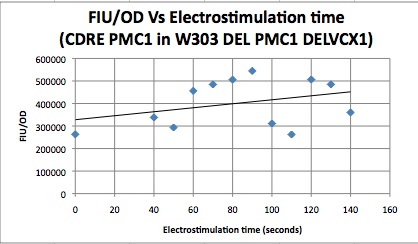

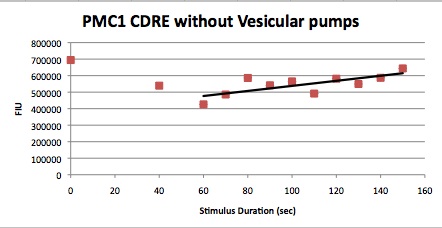

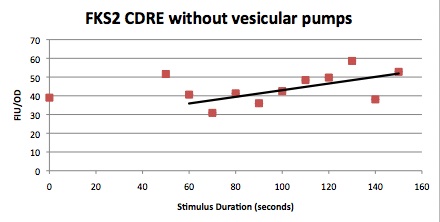

Characterization Of CDRE-RFP system in wild type yeast and PMC1-YFP system in knockout yeast

Reason for doing the experiment:To characterize the relationship between electrostimulation times and expression of florescent protein of the synthetic CDRE promoter sequence and the PMC1 promoter sequence. Also to demonstrate the effect of knocking out the PMC1 and VCX1 genes in yeast.

Date:10/7/10

Location:Ostermeier Complex

Name of S. cerevisiae strain:W303 with CDRE-RFP, Delta VCX1 Delta PMC1 W303 with PMC-YFP

Results

Protocol

Plasmid Extraction

Reagents:

- Buffer P1 - Resuspension Buffer

50mM Tris-Cl, pH 8.0, 10mM EDTA, 100ug/mL RNase A

Storage condition - 4oC after adding RNase A

Prep - Dissolve 6.06g Tris base, 3.72g EDTA-2H20 in 800mL dH20. Adjust the pH to 8.0 with HCl.

Adjust the volume to 1 liter with dH2O. Add 100mg RNase A per liter of P1. - Buffer P2 - Lysis Buffer

200mM NaOH, 1% SDS

Storage condition - RT

Dissolve 8.09g of NaOH pellets in 950mL dH2O, 50mL 20% SDS solution.

The final volume should be 1 liter. - Buffer N3 - Neutralization Buffer for spin columns.

Composition unknown

Storage condition - RT - PB Buffer - Binding Buffer

Composition Unknown (Proprietary)

Storage condition - RT - Buffer PE - Wash Buffer

Composition unknown

Storage condition - RT

Protocol:

- Innoculate 3-4 mL of the E. coli cells in glass tubes with the right selection resistance in LB (Luria Bertani) medium.

- Transfer solution to a 2 mL Eppendorf tube and spin down at max speed (~13,000 rpm) for 30 seconds.

- Pour out LB medium and repeat until all of the solution from the innoculation tube is pelleted at the bottom of the Eppendorf tube. Each spin down after the first requires one full minute.

- Re-suspend the pelleted E. coli in 250 µL Buffer P1 and transfer solution to micro-centrifuge tube provided by the Qiaprep Kit. (This can be the same tube as the 2 mL Eppendorf tube) This step requires a strong vortex in order to fully re-suspend the pelleted cells. May require 3-4 minutes of continuous agitation.

- Add 250 µL of Buffer P2 and mix gently by inverting the tube 4-6 times. Be very gentle! Shear stresses can ruin the experiment after the lysis of cells from P2 Buffer.

- Add 350 µL of Buffer N3 and mix immediately and thoroughly by inverting the tube 4-6 times.

- Spin down at max speed for 10 minutes. A white pellet near the bottom and side of the walls will form.

- Extract the supernatant and add 500 µL of PB buffer. Place mixture into the Qiaprep spin column.

- Centrifuge mixture for 1 minute, max speed.

- Remove liquid at bottom.

- Add 750 µL of PE Buffer to Qiaprep spin column.

- Centrifuge mixture for 1 minute, max speed.

- Remove liquid at bottom and centrifuge again for 1 minute at max speed to remove more of the PE buffer.

- Transfer Qiaprep spin column to sterile Eppendorf tube and add 50 µL of dH2O and let the spin column equilibrate for 10 minutes with the dH2O.

- Spin down column for 1 minute, max speed.

- Confirm size with gel electrophoresis with 1% agarose gel and appropriate DNA Ladder. (Remember circular plasmids can become supercoiled and produce smaller apparent sizes on the gel)

- Use Nanodrop™ to confirm DNA concentration.

Yeast Transformation

To transform a desired plasmid into a host yeast cell.

Date: 8/25/10 Used to transform ref-GFP

Reagents:

- PEG-TE LiOAc

10 mL 10x TE

10 mL 1 M LiOAc

80 mL 50% PEG (3350 mw)

Mix with stir bar, filter sterilize, store at 4 °C - TE-LiOAc

10 mL 10x TE

10 mL 1 M LiOAc

80 mL H2O

- 10x TE

70 mL Tris Base (1M)

30 mL 1M Tris-Cl

20 mL 0.5 M EDTA: pH 8.0

880 mL diH2O

Autoclave: 45 min - SsDNA-(Stratagene #201190-81)

Sonicated Salmon Sperm DNA

ssDNA: 10mg/mL; 1 mL vial

Store at -20°C - 1 M Lithium Acetate-(LiOAc: Sigm L-6883)

102.0 g LiOAc

Bring to 1L diH2O

Autoclave 45 min. - 50% PEG-3350-(Sigma P-4338)

250g PEG to 250 mL warm diH2O

Bring to 500 mL diH2O

Filter Sterilize

Protocol

- Grow yeast cells to log phase in 5 mL YPD medium overnight @ 30 degrees.

- Harvest (5 min, 2000 rpm);aspirate supernatant (sterile tip).

- Wash cell pellet 1X with 1mL TE-LiOAc; transfer to eppendorph tubes.

- Resuspend in 100 µL of TE-LiOAc.

- Add (mix after each):

- 2.5µL Fresh Boiled ssDNA (10 mg/mL)

- 1µL Mini-Prep Plasmid DNA

- 800µL PEG - TE -LiOAc

- Incubate @ 30 C; 30 min. Heat Shock 42 C; ~20 minutes.

- Harvest cells (30 sec,~14000 rpm), aspirate supernatant.

- Wash pellet 1x with 1 mL of YPD.

- Resuspend in 100-250 µL of YPD. Plate onto YPD. Incubate plates 2 days at 30 C.

(Optional: plate onto YPD for 1 day and then replica-plate onto selective medium)

CDRE Optimization

Protocol

A 96 well plate was set up with 2 rows of PMC1 and VCX1 knocked out yeast cells, with the CDRE – RPF plasmid in them. Two rows below that were filled with yeast cells with no knockouts and the CDRE – RFP plasmid inserted in it. We also set aside 8 wells at the bottom as cleaning wells and filled them with ethanol.

The shocking of the cells was carried out using a coaxial electrode system, consisting of 8 sets of gold plated electrodes that fit into the 8 wells of a 96 well plate. An oscilloscope was connected in parallel to the electrode. The shocking was done at 8 V and at 20HZ frequency. The pulses were all sinusoidal.

The cells were shocked for increasing time intervals from 30 seconds to 130 seconds in ten second increments. There was also a 0 second control for every row of cells. Between each shocking the electrodes were first repeatedly dipped in the ethanol wells to clean them and then dipped in a water bath to remove any residual ethanol, then dried using Kim wipes.

After shocking the 96 well plate was put in a shaker at 37C for 8 hours. They were then imaged using a Meta 510 confocal microscope. A 60X oil objective was used and Rodamine and FIT-C filters were applied.

After re suspending any settled cells in the well being tested, 20ul of the cell solution was pipetted onto a slide and a cover slip was placed over it. Some oil was spread on the cover slip and the cells were imaged. At least 2 pictures were taken from each sample.

CDRE Hone in

Procedure

A 96 well plate was set up with 2 rows of PMC1 and VCX1 knocked out yeast cells, with the CDRE – RPF plasmid in them. Two rows below that were filled with yeast cells with no knockouts and the CDRE – RFP plasmid inserted in it. We also set aside 8 wells at the bottom as cleaning wells and filled them with ethanol.

The shocking of the cells was carried out using a coaxial electrode system, consisting of 8 sets of gold plated electrodes that fit into the 8 wells of a 96 well plate. An oscilloscope was connected in parallel to the electrode. The shocking was done at 8 V and at 20HZ frequency. The pulses were all sinusoidal.

The cells were shocked for increasing time intervals from 30 seconds to 130 seconds in ten second increments. There was also a 0 second control for every row of cells. Between each shocking the electrodes were first repeatedly dipped in the ethanol wells to clean them and then dipped in a water bath to remove any residual ethanol, then dried using Kim wipes. After shocking the 96 well plate was put in a shaker at 37C for 8 hours. They were then imaged using a Meta 510 confocal microscope. A 60X oil objective was used and Rodamine and FIT-C filters were applied.

After re suspending any settled cells in the well being tested, 20ul of the cell solution was pipetted onto a slide and a cover slip was placed over it. Some oil was spread on the cover slip and the cells were imaged. At least 2 pictures were taken from each sample.

Characterization Of CDRE-RFP system in wild type yeast and PMC1-YFP system in knockout yeast

Procedure

A 96 well plate was set up with 1 rows of W303 yeast cells, with the CDRE – RPF plasmid in them. One row below that were filled with yeast cells with PMC1 and VCX1 knocked out the PMC1 - YFP plasmid inserted in it.

The shocking of the cells was carried out using a coaxial electrode system, consisting of 8 sets of gold plated electrodes that fit into the 8 wells of a 96 well plate. An oscilloscope was connected in parallel to the electrode. The shocking was done at 8 V and at 20HZ frequency. The pulses were all sinusoidal.

The cells were shocked for increasing time intervals from 40 seconds to 150 seconds in ten second increments. There was also a 0 second control for every row of cells. Between each shocking the electrodes were first repeatedly dipped in the ethanol wells to clean them and then dipped in a water bath to remove any residual ethanol, then dried using Kim wipes. After shocking the 96 well plate was put in a shaker at 37C for 8 hours.

These cells were then put in a plate reader that measured OD, as a measure of cell growth in the samples over the expression period of 8 hours. After this the plate was put in a plate florometer and RFP and YFP intensities were measured. The following data was collected.

| Time/FIU/OD | CDRE | PMC1 |

|---|---|---|

| 0 | 17.85119048 | 263121.1632 |

| 40 | 26.10337553 | 338282.2967 |

| 50 | 19.86680328 | 293471.7742 |

| 60 | 29.04337349 | 456021.0843 |

| 70 | 28.32403433 | 484804.1237 |

| 80 | 33.50247525 | 505993.6102 |

| 90 | 34.32098765 | 544573.5294 |

| 100 | 29.03455724 | 311173.5358 |

| 110 | 34.65552699 | 262445.7237 |

| 120 | 32.08673469 | 506424.9201 |

| 130 | 41.87246377 | 485111.8881 |

| 140 | 37.71948052 | 360177.9279 |

Characterization Of CDRE-RFP and PMC1-YFP system in wild type yeast and in knockout yeast

Procedure

Two 96 well plates were set up with one having 4 rows of W303 yeast cells, with the CDRE – RPF plasmid in them. 4 rows below them were filled with yeast cells with PMC1 and VCX1 knocked out and the CDRE-RFP plasmid inserted in them.

The other has 4 rows of W303 yeast cells, with the CDRE – RPF plasmid in them. 4 rows below them were filled with yeast cells with PMC1 and VCX1 knocked out and the CDRE-RFP plasmid inserted in them.

The shocking of the cells was carried out using a coaxial electrode system, consisting of 8 sets of gold plated electrodes that fit into the 8 wells of a 96 well plate. An oscilloscope was connected in parallel to the electrode. The shocking was done at 8 V and at 20HZ frequency. The pulses were all sinusoidal.

The cells were shocked for increasing time intervals from 40 seconds to 150 seconds in ten second increments. There was also a 0 second control for every row of cells. Between each shocking the electrodes were first repeatedly dipped in the ethanol wells to clean them and then dipped in a water bath to remove any residual ethanol, then dried using Kim wipes. After shocking the 96 well plate were allowed to grow at room temperature.

These cells were then put in a plate reader that measured OD, as a measure of cell growth in the samples over the expression period of 8 hours. After this the plate was put in a plate florometer and RFP and YFP intensities were measured. The growth and expression was so measured at one hour intervals from three hours later to 8 hours later. The following data was collected.

Plasmid Extraction

Reagents:

- Buffer P1 - Resuspension Buffer

50mM Tris-Cl, pH 8.0, 10mM EDTA, 100ug/mL RNase A

Storage condition - 4oC after adding RNase A

Prep - Dissolve 6.06g Tris base, 3.72g EDTA-2H20 in 800mL dH20. Adjust the pH to 8.0 with HCl.

Adjust the volume to 1 liter with dH2O. Add 100mg RNase A per liter of P1. - Buffer P2 - Lysis Buffer

200mM NaOH, 1% SDS

Storage condition - RT

Dissolve 8.09g of NaOH pellets in 950mL dH2O, 50mL 20% SDS solution.

The final volume should be 1 liter. - Buffer N3 - Neutralization Buffer for spin columns.

Composition unknown

Storage condition - RT - PB Buffer - Binding Buffer

Composition Unknown (Proprietary)

Storage condition - RT - Buffer PE - Wash Buffer

Composition unknown

Storage condition - RT

Protocol:

- Innoculate 3-4 mL of the E. coli cells in glass tubes with the right selection resistance in LB (Luria Bertani) medium.

- Transfer solution to a 2 mL Eppendorf tube and spin down at max speed (~13,000 rpm) for 30 seconds.

- Pour out LB medium and repeat until all of the solution from the innoculation tube is pelleted at the bottom of the Eppendorf tube. Each spin down after the first requires one full minute.

- Re-suspend the pelleted E. coli in 250 µL Buffer P1 and transfer solution to micro-centrifuge tube provided by the Qiaprep Kit. (This can be the same tube as the 2 mL Eppendorf tube) This step requires a strong vortex in order to fully re-suspend the pelleted cells. May require 3-4 minutes of continuous agitation.

- Add 250 µL of Buffer P2 and mix gently by inverting the tube 4-6 times. Be very gentle! Shear stresses can ruin the experiment after the lysis of cells from P2 Buffer.

- Add 350 µL of Buffer N3 and mix immediately and thoroughly by inverting the tube 4-6 times.

- Spin down at max speed for 10 minutes. A white pellet near the bottom and side of the walls will form.

- Extract the supernatant and add 500 µL of PB buffer. Place mixture into the Qiaprep spin column.

- Centrifuge mixture for 1 minute, max speed.

- Remove liquid at bottom.

- Add 750 µL of PE Buffer to Qiaprep spin column.

- Centrifuge mixture for 1 minute, max speed.

- Remove liquid at bottom and centrifuge again for 1 minute at max speed to remove more of the PE buffer.

- Transfer Qiaprep spin column to sterile Eppendorf tube and add 50 µL of dH2O and let the spin column equilibrate for 10 minutes with the dH2O.

- Spin down column for 1 minute, max speed.

- Confirm size with gel electrophoresis with 1% agarose gel and appropriate DNA Ladder. (Remember circular plasmids can become supercoiled and produce smaller apparent sizes on the gel)

- Use Nanodrop™ to confirm DNA concentration.

Yeast Transformation

To transform a desired plasmid into a host yeast cell.

Date: 8/25/10 Used to transform ref-GFP

Reagents:

- PEG-TE LiOAc

10 mL 10x TE

10 mL 1 M LiOAc

80 mL 50% PEG (3350 mw)

Mix with stir bar, filter sterilize, store at 4 °C - TE-LiOAc

10 mL 10x TE

10 mL 1 M LiOAc

80 mL H2O

- 10x TE

70 mL Tris Base (1M)

30 mL 1M Tris-Cl

20 mL 0.5 M EDTA: pH 8.0

880 mL diH2O

Autoclave: 45 min - SsDNA-(Stratagene #201190-81)

Sonicated Salmon Sperm DNA

ssDNA: 10mg/mL; 1 mL vial

Store at -20°C - 1 M Lithium Acetate-(LiOAc: Sigm L-6883)

102.0 g LiOAc

Bring to 1L diH2O

Autoclave 45 min. - 50% PEG-3350-(Sigma P-4338)

250g PEG to 250 mL warm diH2O

Bring to 500 mL diH2O

Filter Sterilize

Protocol

- Grow yeast cells to log phase in 5 mL YPD medium overnight @ 30 degrees.

- Harvest (5 min, 2000 rpm);aspirate supernatant (sterile tip).

- Wash cell pellet 1X with 1mL TE-LiOAc; transfer to eppendorph tubes.

- Resuspend in 100 µL of TE-LiOAc.

- Add (mix after each):

- 2.5µL Fresh Boiled ssDNA (10 mg/mL)

- 1µL Mini-Prep Plasmid DNA

- 800µL PEG - TE -LiOAc

- Incubate @ 30 C; 30 min. Heat Shock 42 C; ~20 minutes.

- Harvest cells (30 sec,~14000 rpm), aspirate supernatant.

- Wash pellet 1x with 1 mL of YPD.

- Resuspend in 100-250 µL of YPD. Plate onto YPD. Incubate plates 2 days at 30 C.

(Optional: plate onto YPD for 1 day and then replica-plate onto selective medium)

Plasmid Mini-Prep

Reagents

- Solutions 1 (Glucose/Tris/EDTA Solution):

2.3 mL 40% Glucose (50 mM Glucose)

2.5 mL Tris-Cl (25 mM Tris-Cl pH 8.0)

2 mL EDTA .5M (10 mM EDTA)

Bring to 100 mL with diH2O

keep refrigerated

- Solution II (NaOH/ SDS solution):

Mix (in order):

Make 10 mL fresh each time:

7.5 mL diH20

2 mL of 1N NaOH

0.5 mL of 20% SDS

Adjust the volume to 10 mL with diH2O after both SDS and NaOH have been added

- Solution III (KOAc solution):

to make 100 mL; add:

60 mL 5 M KOAc

11.5 mL glacial acetic acid

28.5 mL diH2O

keep refrigerated

pH should be around 6.0

Protocol:

- Innoculate 5 mL of sterile growth medium containing appropriate antibiotic with a single bacterial colony. Incubate at 37 C in the incubator shaker. Allow to grow until a stationary phase is reached (overnight is ideal).

- Transter 2 x 750 µL aliquots from each overnight culture into a labeled eppendorf tube. Pellet the cells by spinning for 3 to 5 minutes in the microfuge at maximum speed.

- Aspirate as much of supernatant as possible.

- Resuspend the cell pellet in 100 µL of Solution I. Use pipetman to suck the solution up and down until the pellet is completely resuspended in the lysis buffer.

- Let samples sit at room temp for 5 minutes. (Unless using TE, then skip this step)

- Add 200 µL of Solution II (make fresh each time). Mix well, vortex if necessary. Let stand on ice for 5 minutes. The samples should get gooey and might have stringy webs when opened.

- Add 150 µL of cold Solution III and vortex at highest speed for 2 sec to mix, let stand on ice for 5 minutes. (Here the chromosomal DNA and the cellular proteins appear as a precipitate. The plasmid DNA renatures and remains in solution.) The tubes can stand on ice for several hours if necessary.

- Spin for 5 to 10 minutes in the cold room microfuge to pellet the cell debris and chromosomal DNA.

- While the tubes are spinning, set up fresh labeled tubes each with 2 volumes of cold 100% EtOH. If you had 400 µL of supernatant from the above step, use 800 µL of ethanol.

- Carefully remove the top aqueous layer of each tube from step 8 with a 1 mL pipetman (usually about 400 µL) and dispense into the tubes containing the cold 100% ethanol.

- Let stand on ice for 5 minutes (or longer) to precipitate the nucleic acids. Alternatively, place in the freezer for a longer period. The DNA is stable in ethanol and can be held at this step for as long as necessary.

- Spin for 5 to 10 minutes (or longer) in the microfuge to pellet the plasmid DNA and RNA.

- Remove and discard the supernatant, being careful to not disturb the pellet and dry on a kimwipe if needed.

- Add 1 mL of 70% EtOH to rinse DNA. Spin for 5 minutes

- Remove and discard the supernatant.

- Dry the pellets by placing the samples in the Speed-Vac and dry under vacuum for 5 to 10 minutes (make sure pellet is dry).

- Dissolve pellet in 30 µL of H2O (or TE). Gently agitate the tube by tapping on the side to insure that the pellet has been resuspended. The tubes can be incubated at 37 C to aid in resuspension.

- Refrigerate until ready to use.

SC Media

Reagents:

| gms | mg/L | gms | mg/L | ||

|---|---|---|---|---|---|

| Adenine sulfate | 12 | 20 | L-Isoleucine | 18 | 30 |

| Uracil | 12 | 20 | L-Lysine | 18 | 30 |

| L-Tryptophan | 12 | 20 | L-Phenylalanine | 30 | 50 |

| L-Leucine | 12 | 20 | L-Glutamic acid | 60 | 100 |

| L-Histadine | 12 | 20 | L-Aspartic acid | 60 | 100 |

| L-Arginine | 12 | 20 | L-Valine | 90 | 150 |

| L-Methionine | 12 | 20 | L-Threonine | 120 | 200 |

| L-Tyrosine | 18 | 30 | L-Serine | 240 | 400 |

| L-Leucine | 36 | 60 | Glucose | 12 | 20 |

| L-Isoleucine | 18 | 30 |

Selective media is made by omitting the desired amino acid(s).

Digestion and ligation of plasmids

Plates

| YPD | ml | SC- | ml |

|---|---|---|---|

| 40% Dextrose | 30 | 40% Dextrose | 30 |

| 2X YEP | 300 | Selective Media | 300 |

| 4% Agar | 300 | 4% Agar | 300 |

Protocol

| Plasmid\Reagents (µL) | DNA | Xba1 | Pst1 | Buffer | BSA | Water |

|---|---|---|---|---|---|---|

| pSB1C3 (50ng/µL) | 33 | 4 | 0.07 | 10 | 1 | 51.88 |

| GTGGCTG (283ng/µL) | 0.71 | 30.84 | 0.55 | 40 | 4 | 323.91 |

| GAGGCTG (343ng/µL) | 0.58 | 3.0.84 | 0.55 | 35 | 3.5 | 279.53 |

| GAGGCTC (324ng/µL) | 0.62 | 30.84 | 0.55 | 35 | 3.5 | 279.5 |

| GAGGCGG (235ng/µL) | 0.93 | 33.92 | 0.61 | 35 | 3.5 | 276.04 |

| GAGGCTT (356ng/µL) | 0.62 | 33.92 | 0.61 | 35 | 3.5 | 276.36 |

| CAGGCTG (345ng/µL) | 0.64 | 33.92 | 0.61 | 35 | 3.5 | 276.34 |

| GGGGCTG (293ng/µL) | 0.75 | 33.92 | 0.61 | 35 | 3.5 | 276.22 |

These solutions are incubated at 37ºC for one hour. Gel purification used 0.8% agarose TAE gel, visualized with ethidium bromide and UV light. Qiagen’s gel purification kit protocol was followed, with the exception of the ethanol-wash step, which was repeated twice. Zymogen’s Clean and Concentrate protocal was followed to further purify the DNA.

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

"

"