Team:Groningen/19 July 2010

From 2010.igem.org

Week 29

Modellers:

After lots of meetings the time has come to really start up the modelling part of iGEM. This week we thought about what to model and how. We have looked up and read lots of articles.

David

Drying biofilms

After formation of biofilm on the pieces of wood and ceramics, the material was taken out of the wells plates and put into empty petri dishes. This was put into the 37 C oven for 3 days. Inspection of these dried in biofilms was done by stereomicroscopy.

David & Peter

Dispersant effects chaplin proteins

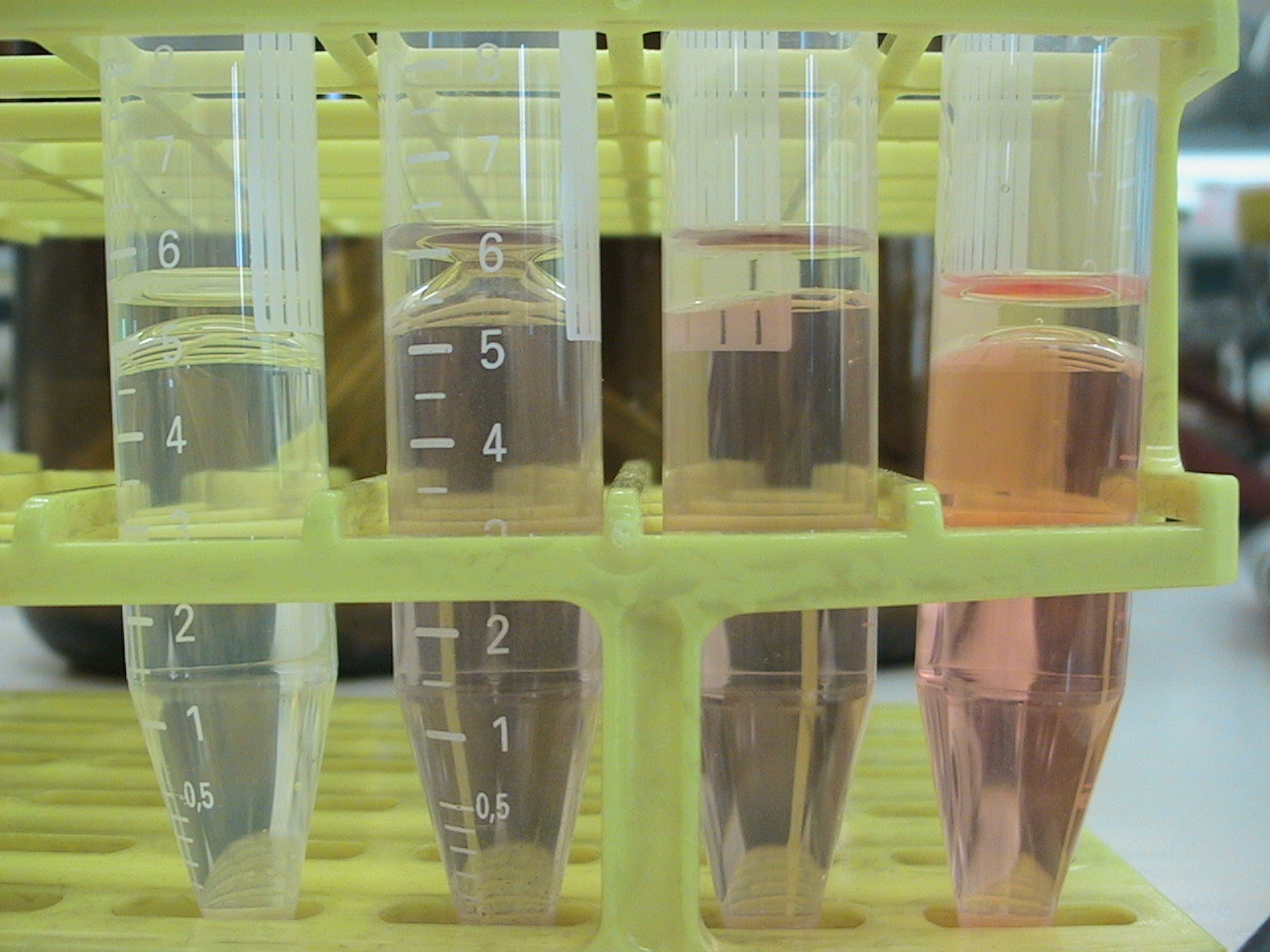

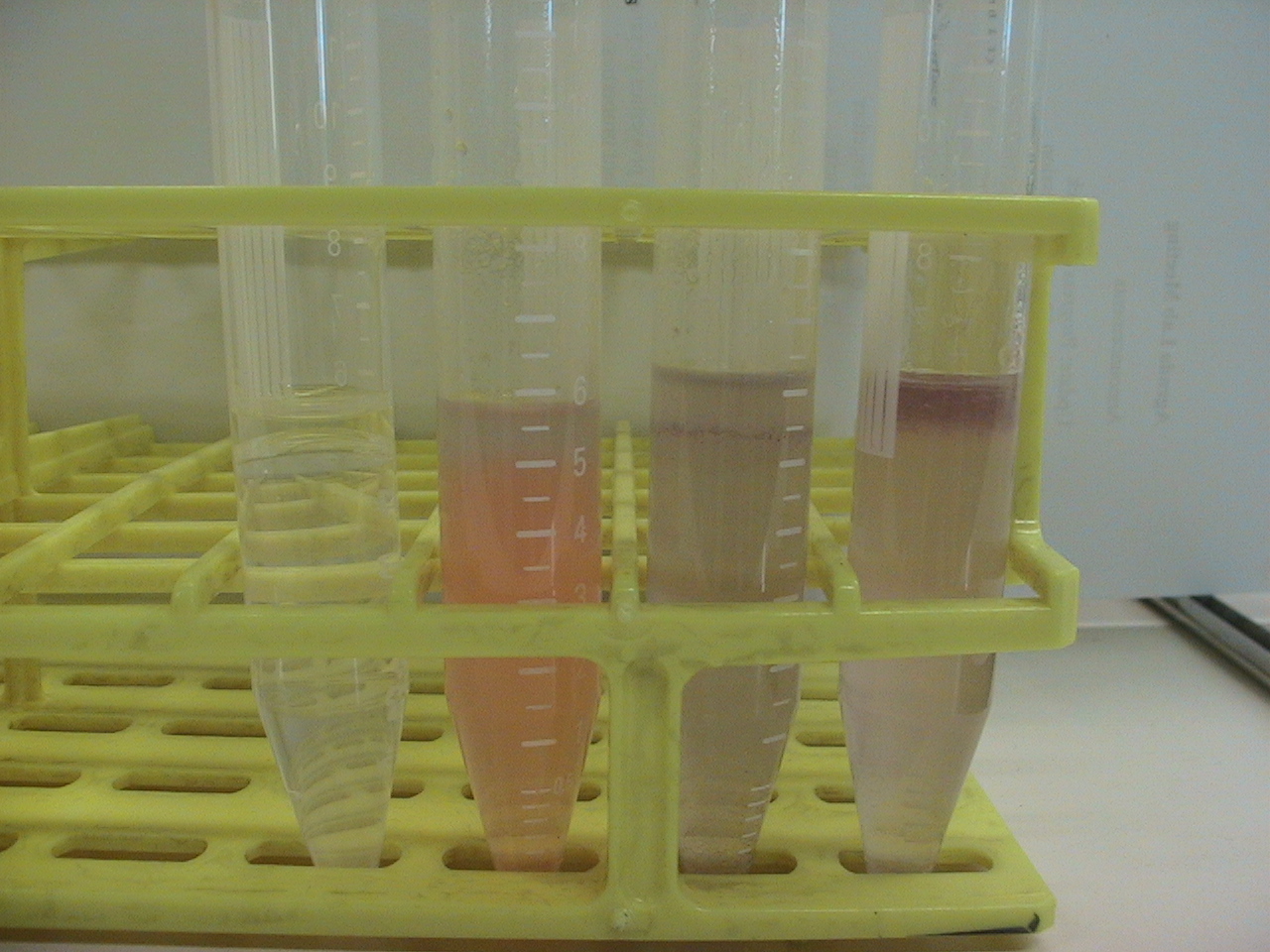

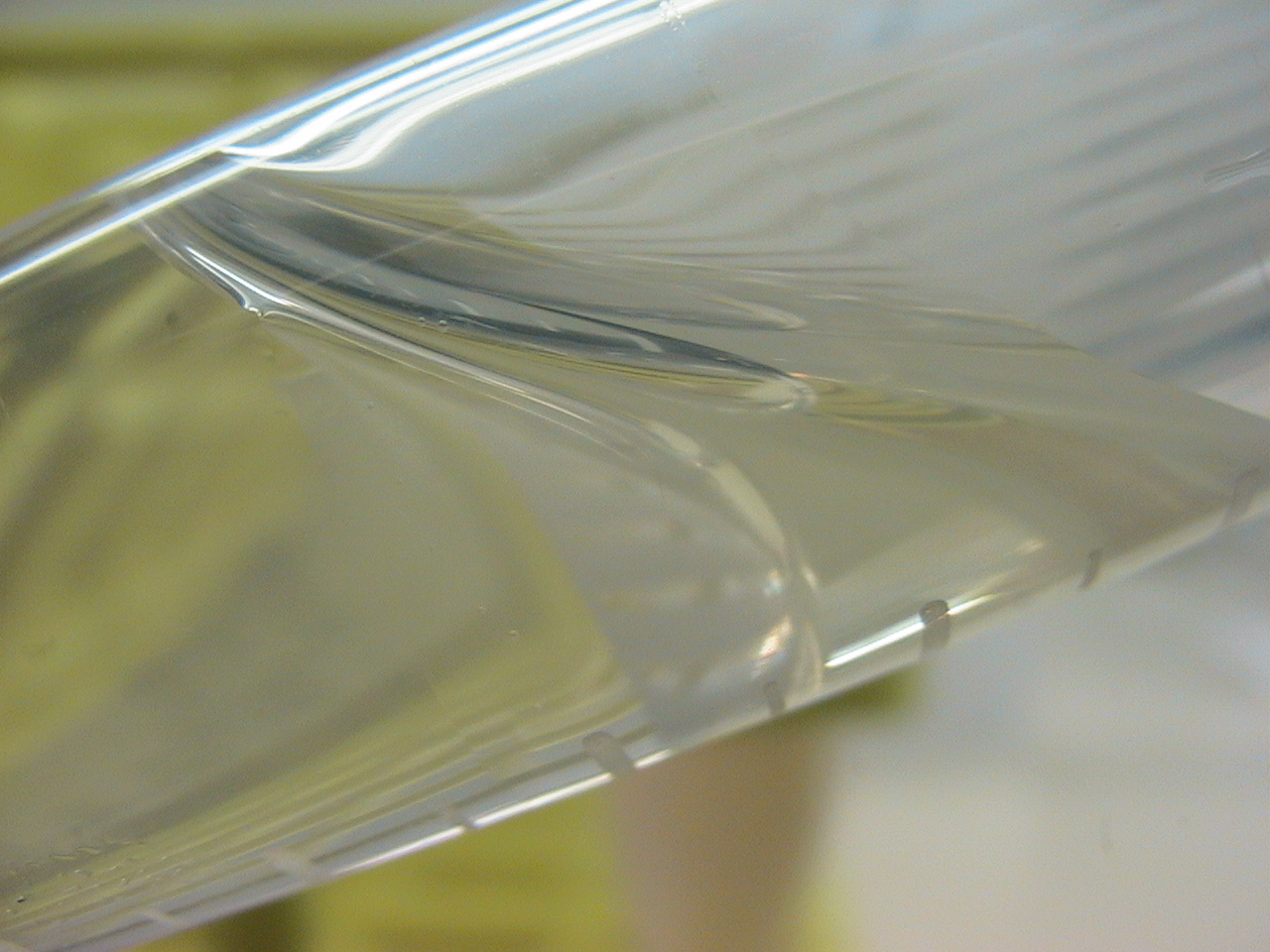

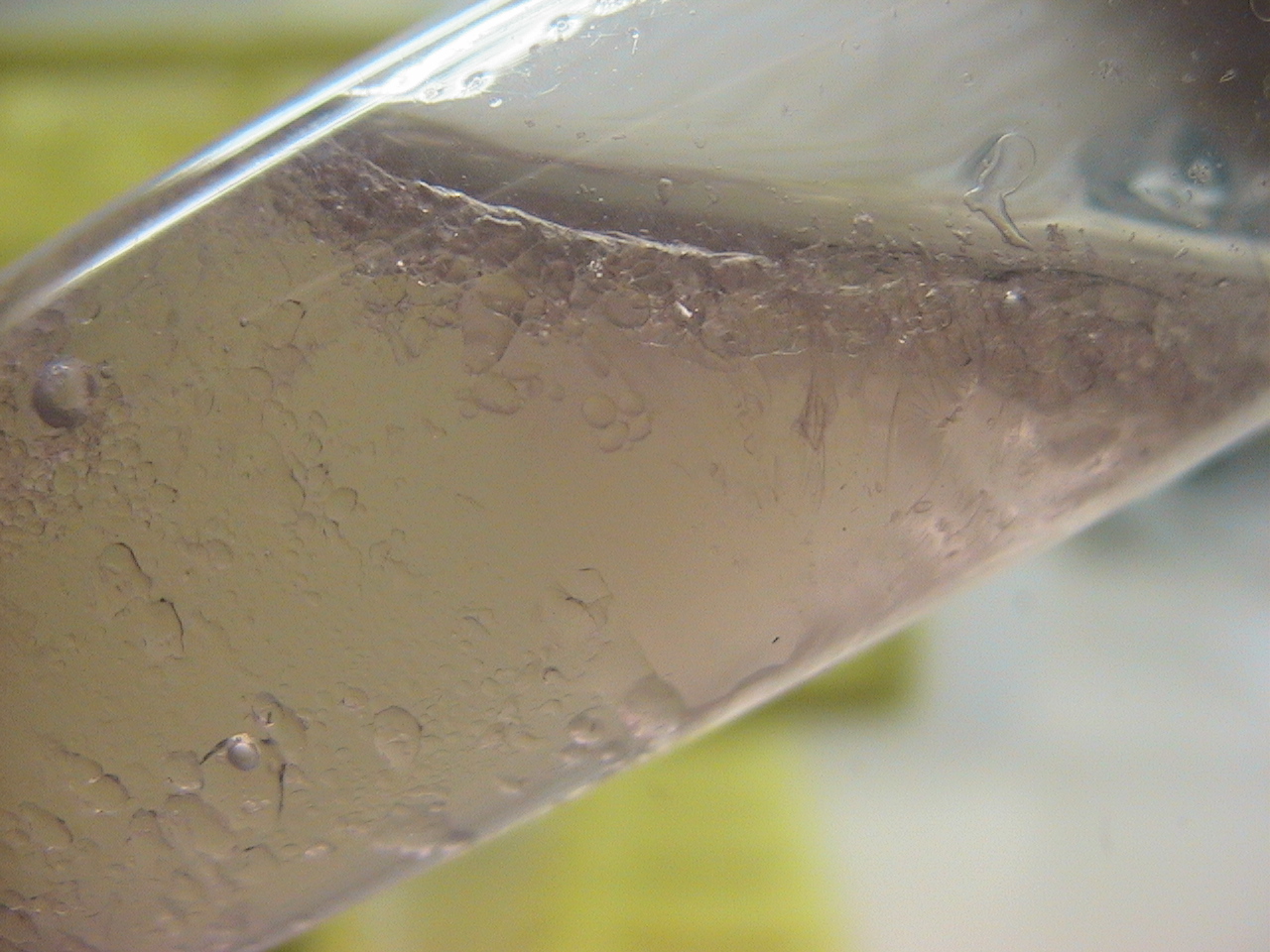

5 ml of demiwater and 0.5 ml olive oil, adding 500 microliter of 15 mg/ml monomeric chaplins to one tube, 0.5 ml vortexed assembled chaplins, and two controls without chpls added. Also ad 30 microliter congo red solution (3 mg/micro liter) to all samples exept one of the two controls. This congo red will stain the assembled chapl Then vortex for 1 min add max speed, then let the samples sit for 10 min. After this closeup pictures are taken of the oil water interface.

Before Shaking

Left to right: Water+oil, Water+oil+CongoRed+AssembledChaplins, Water+Oil+CongoRed+MonomericChaplins, Water+Oil+CongoRed

After Shaking:

Left to right: Water+oil, Water+oil+CongoRed+AssembledChaplins, Water+Oil+CongoRed+MonomericChaplins, Water+Oil+CongoRed

Close ups: Shortly after shaking, left: Control (H20 + Oil), right (Water + Oil + Monomeric Chaplins).

"

"